Pharma Leader Safeguards Drug Safety and Brand Reputation with VisionGuard

Pharma Leader Safeguards Drug Safety and Brand Reputation with VisionGuard

Pharma Leader Safeguards Drug Safety and Brand Reputation with VisionGuard

Pharma Leader Safeguards Drug Safety and Brand Reputation with VisionGuard

Client: A leading pharmaceutical company with a critical need for accurate and reliable quality assurance of vials and ampules.

Challenge: Reliance on manual visual inspection posed significant risks, including missed foreign particles, potential adverse drug reactions, and damage to brand reputation.

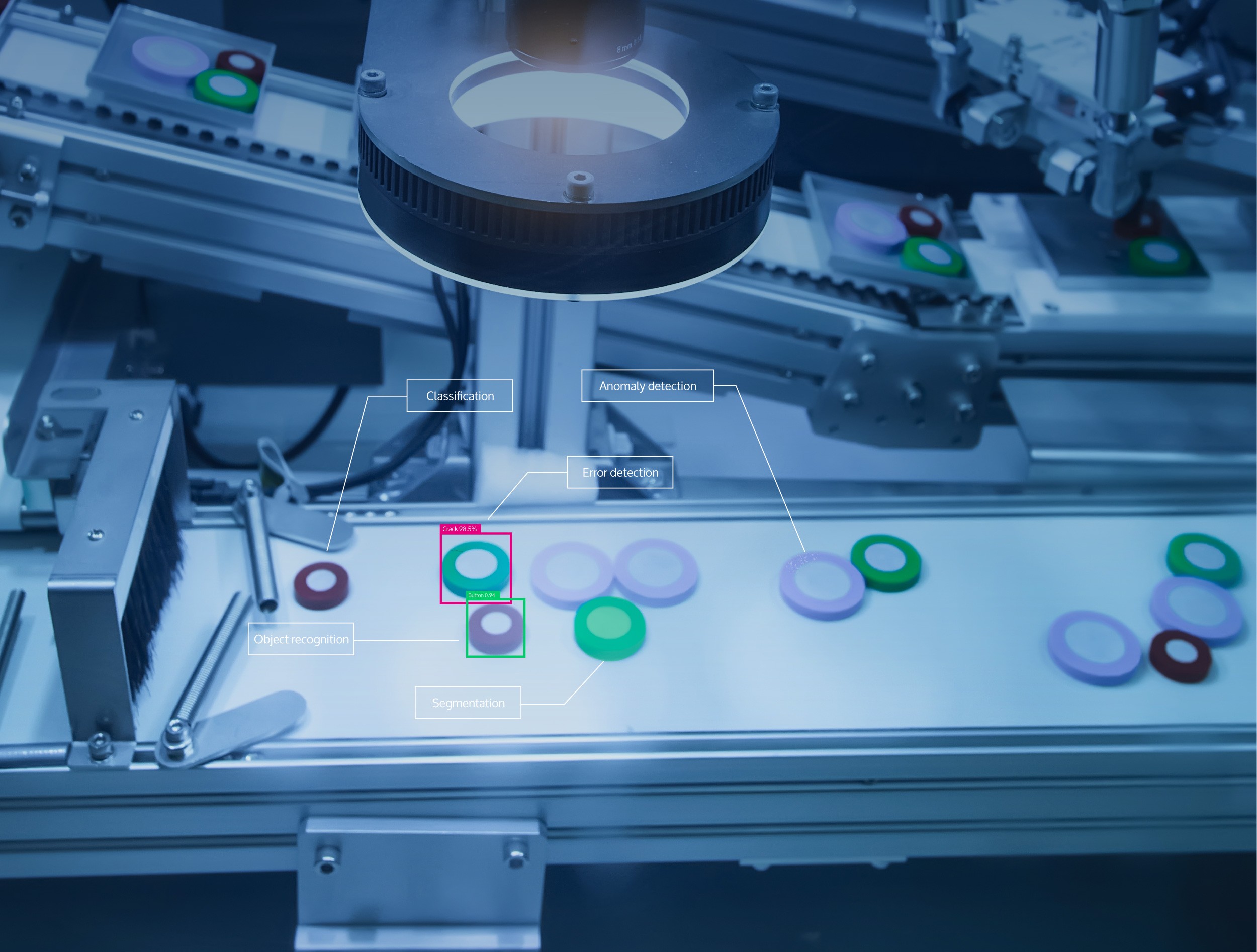

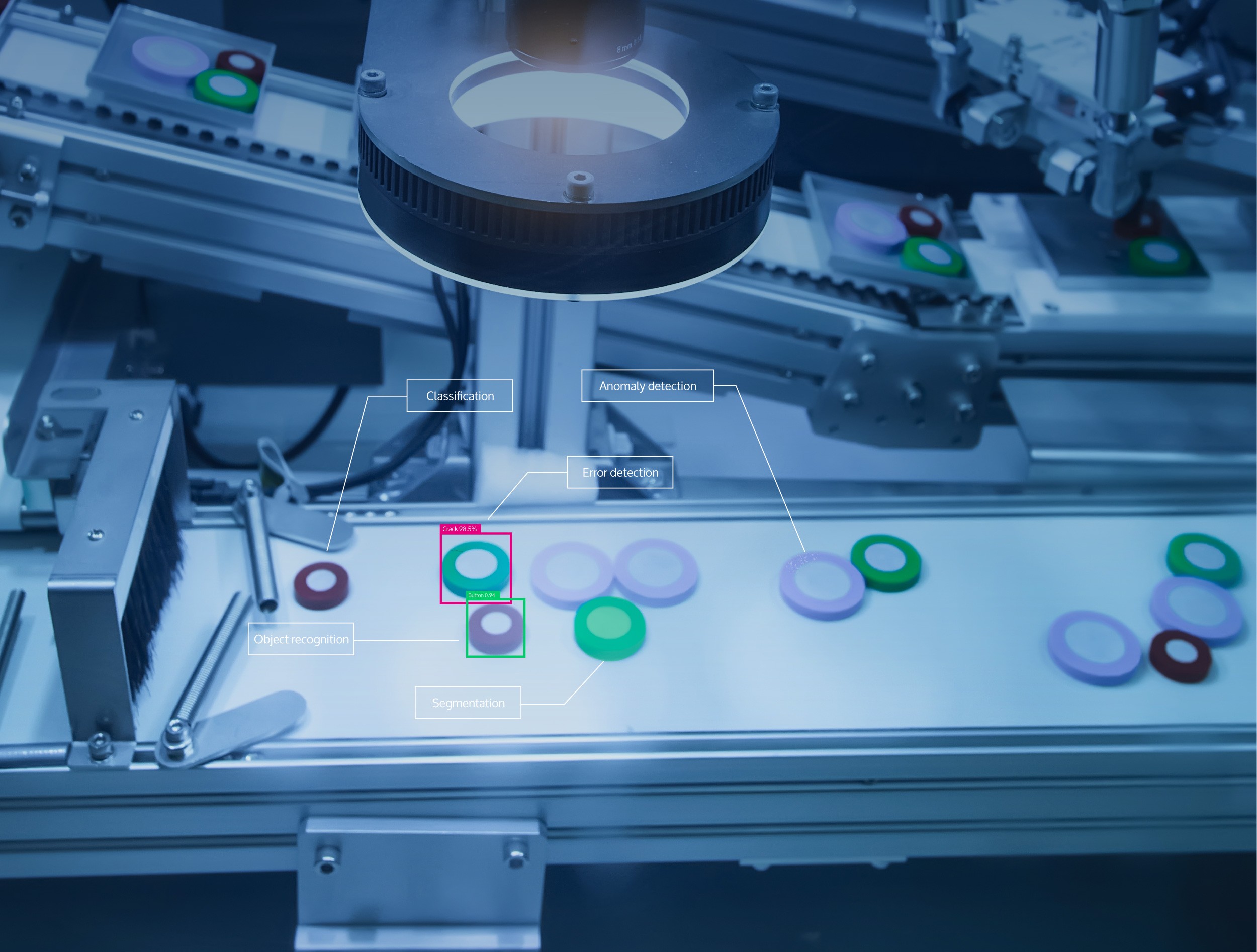

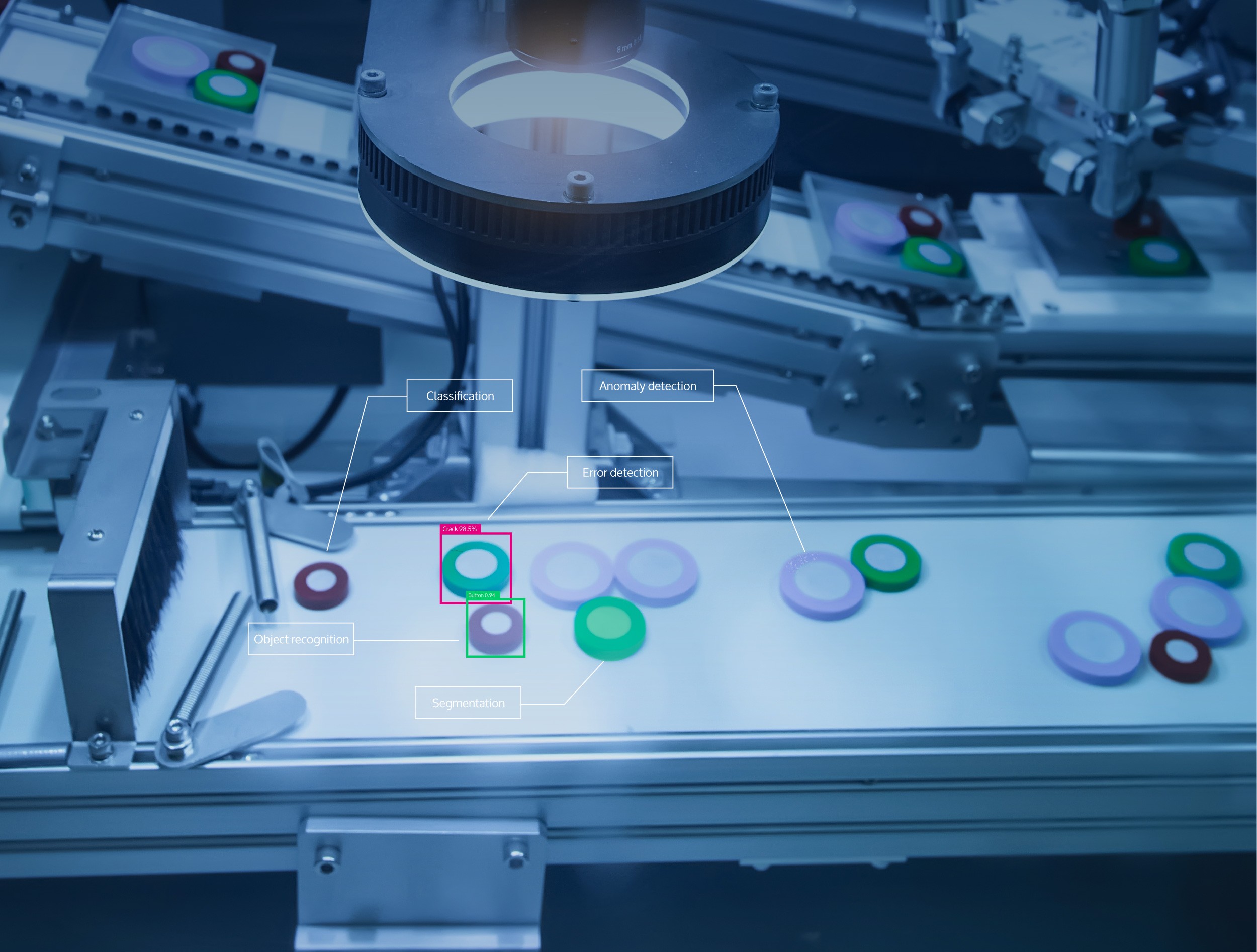

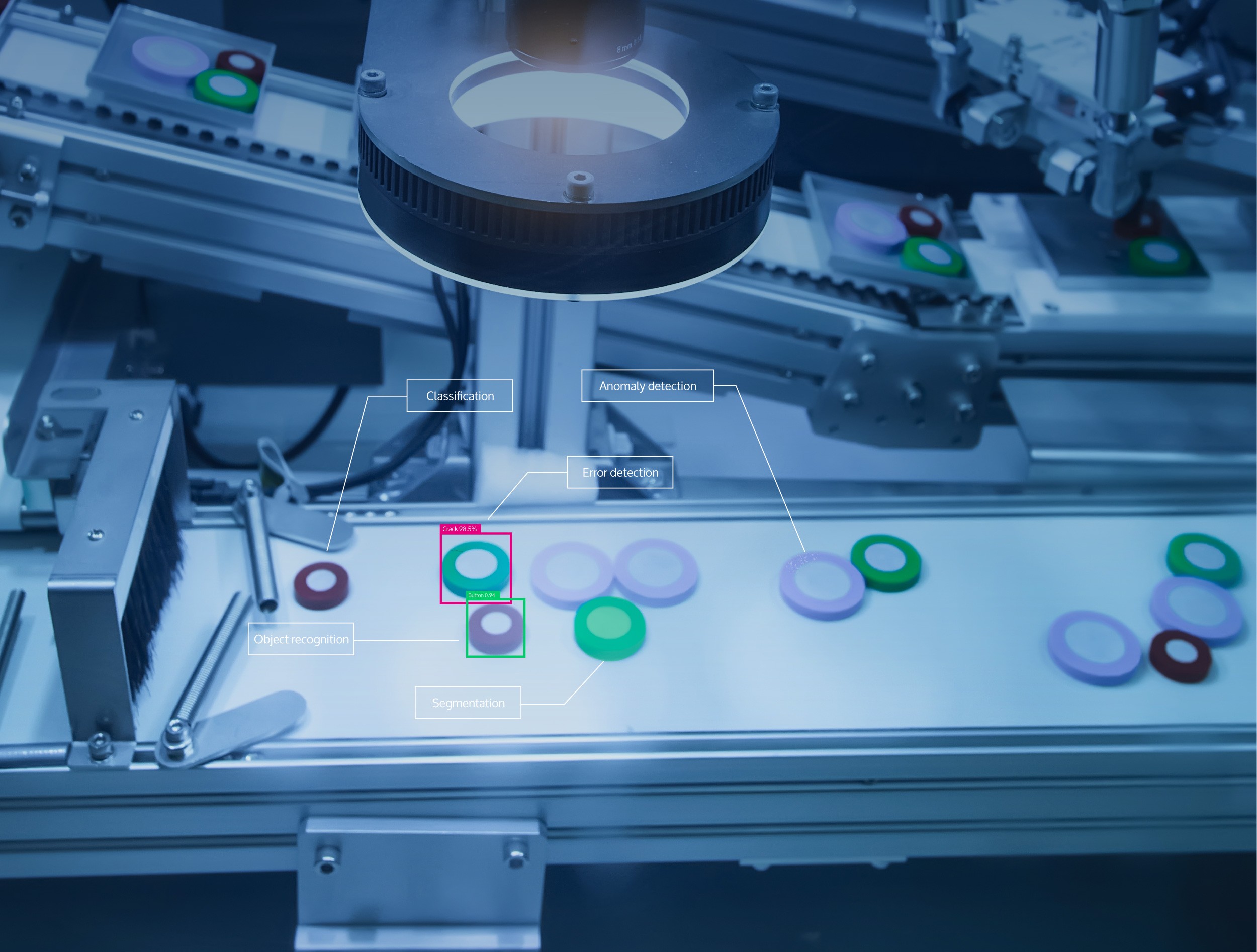

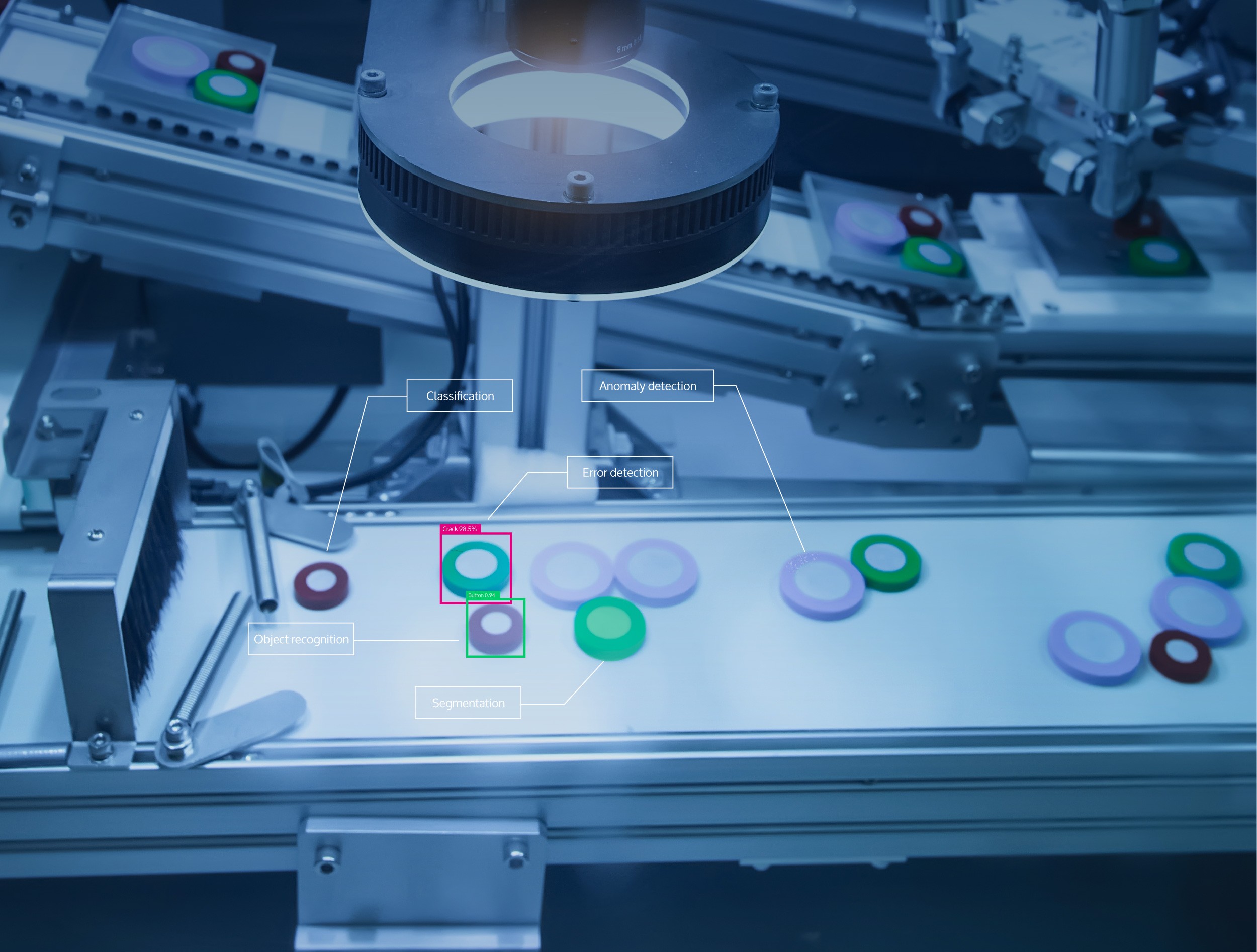

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality assurance.

Results: Significant improvement in accuracy, efficiency, and cost savings, along with enhanced quality control, reduced manual errors, and mitigated risks to patient safety and brand reputation.

Client: A leading pharmaceutical company with a critical need for accurate and reliable quality assurance of vials and ampules.

Challenge: Reliance on manual visual inspection posed significant risks, including missed foreign particles, potential adverse drug reactions, and damage to brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality assurance.

Results: Significant improvement in accuracy, efficiency, and cost savings, along with enhanced quality control, reduced manual errors, and mitigated risks to patient safety and brand reputation.

Client: A leading pharmaceutical company with a critical need for accurate and reliable quality assurance of vials and ampules.

Challenge: Reliance on manual visual inspection posed significant risks, including missed foreign particles, potential adverse drug reactions, and damage to brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality assurance.

Results: Significant improvement in accuracy, efficiency, and cost savings, along with enhanced quality control, reduced manual errors, and mitigated risks to patient safety and brand reputation.

Client: A leading pharmaceutical company with a critical need for accurate and reliable quality assurance of vials and ampules.

Challenge: Reliance on manual visual inspection posed significant risks, including missed foreign particles, potential adverse drug reactions, and damage to brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality assurance.

Results: Significant improvement in accuracy, efficiency, and cost savings, along with enhanced quality control, reduced manual errors, and mitigated risks to patient safety and brand reputation.

Client: A leading pharmaceutical company with a critical need for accurate and reliable quality assurance of vials and ampules.

Challenge: Reliance on manual visual inspection posed significant risks, including missed foreign particles, potential adverse drug reactions, and damage to brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality assurance.

Results: Significant improvement in accuracy, efficiency, and cost savings, along with enhanced quality control, reduced manual errors, and mitigated risks to patient safety and brand reputation.

AI Vision

AI Vision

AI Vision

Quality Assurance

Quality Assurance

Quality Assurance

Pharmaceutical Industry

Pharmaceutical Industry

Pharmaceutical Industry

VisionGuard.AI

VisionGuard.AI

VisionGuard.AI

Risk Mitigation

Risk Mitigation

Risk Mitigation

Compliance

Compliance

Compliance

The Challenge:

High Stakes in Pharmaceutical Quality Assurance

The Challenge:

High Stakes in Pharmaceutical Quality Assurance

The Challenge:

High Stakes in Pharmaceutical Quality Assurance

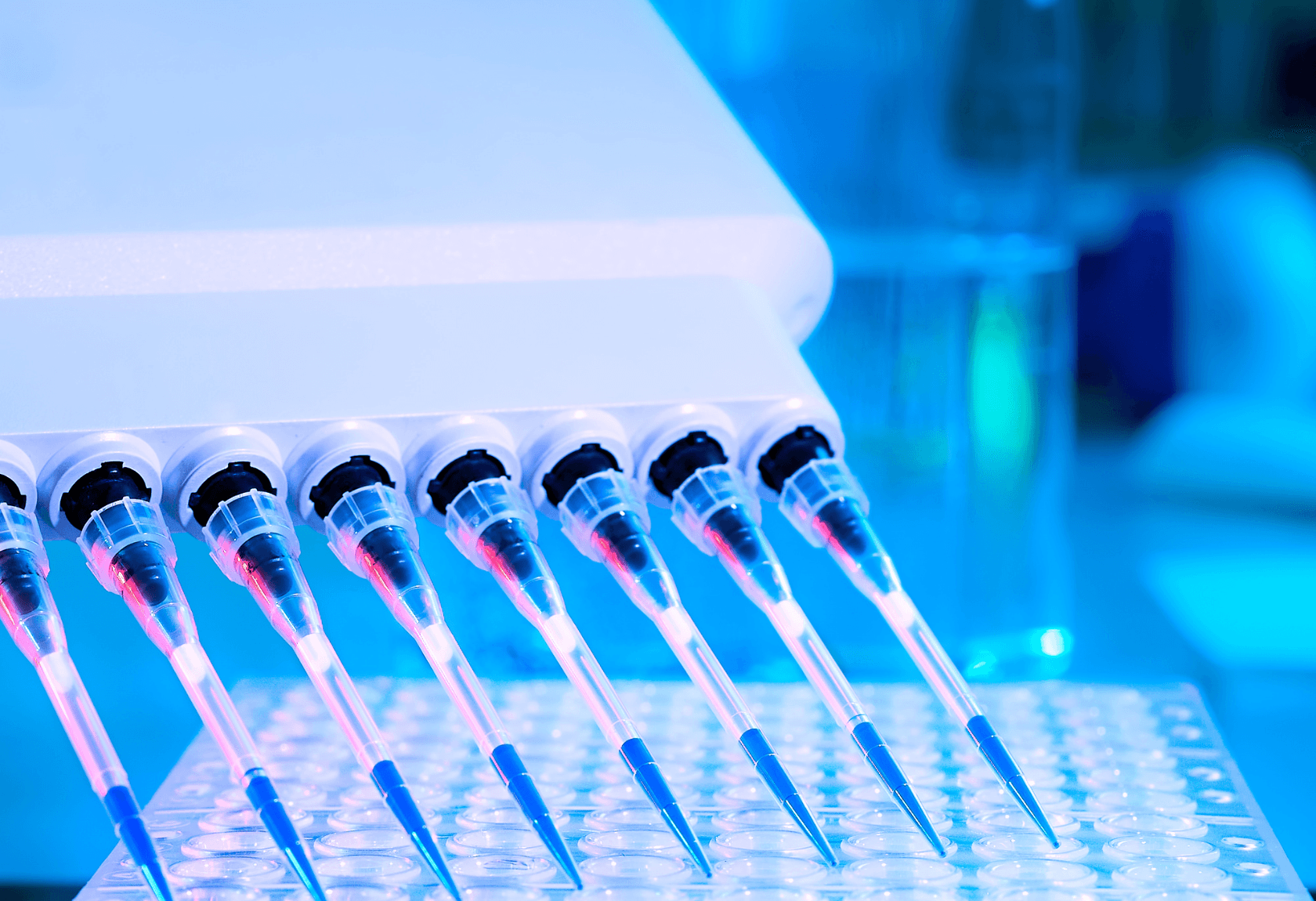

Maintaining the highest quality standards in pharmaceutical manufacturing is paramount, with any compromise potentially leading to severe consequences. Our client, a leading pharma company, faced challenges in their visual inspection process for drug vials and ampules, where the stakes were incredibly high.

Maintaining the highest quality standards in pharmaceutical manufacturing is paramount, with any compromise potentially leading to severe consequences. Our client, a leading pharma company, faced challenges in their visual inspection process for drug vials and ampules, where the stakes were incredibly high.

Maintaining the highest quality standards in pharmaceutical manufacturing is paramount, with any compromise potentially leading to severe consequences. Our client, a leading pharma company, faced challenges in their visual inspection process for drug vials and ampules, where the stakes were incredibly high.

Manual Inspection: The process relied on 45 employees working in shifts to visually inspect vials and ampules against white and black backgrounds, checking for foreign particles and defects.

Manual Inspection: The process relied on 45 employees working in shifts to visually inspect vials and ampules against white and black backgrounds, checking for foreign particles and defects.

Manual Inspection: The process relied on 45 employees working in shifts to visually inspect vials and ampules against white and black backgrounds, checking for foreign particles and defects.

Human Fallibility: Manual inspection was prone to human error and inconsistencies due to fatigue, subjectivity, and the varying sizes of vials and ampules.

Human Fallibility: Manual inspection was prone to human error and inconsistencies due to fatigue, subjectivity, and the varying sizes of vials and ampules.

Human Fallibility: Manual inspection was prone to human error and inconsistencies due to fatigue, subjectivity, and the varying sizes of vials and ampules.

Critical Risks: Any missed foreign particle could lead to an unexpected drug reaction, potentially endangering human life and resulting in heavy legal and compliance costs, irreparable damage to the brand's reputation, and loss of valuable contracts.

Critical Risks: Any missed foreign particle could lead to an unexpected drug reaction, potentially endangering human life and resulting in heavy legal and compliance costs, irreparable damage to the brand's reputation, and loss of valuable contracts.

Critical Risks: Any missed foreign particle could lead to an unexpected drug reaction, potentially endangering human life and resulting in heavy legal and compliance costs, irreparable damage to the brand's reputation, and loss of valuable contracts.

High Labor Costs: The manual process was labor-intensive and costly, requiring significant human resources and operational expenses.

High Labor Costs: The manual process was labor-intensive and costly, requiring significant human resources and operational expenses.

High Labor Costs: The manual process was labor-intensive and costly, requiring significant human resources and operational expenses.

Automation Challenges: Previous attempts to automate the process failed due to the varying sizes and shapes of the vials and ampules.

Automation Challenges: Previous attempts to automate the process failed due to the varying sizes and shapes of the vials and ampules.

Automation Challenges: Previous attempts to automate the process failed due to the varying sizes and shapes of the vials and ampules.

The Solution

The Solution

The Solution

VisionGuard – An AI-Powered Eye for Quality

VisionGuard – An AI-Powered Eye for Quality

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the client's quality assurance process and mitigate the risks associated with manual inspection.

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the client's quality assurance process and mitigate the risks associated with manual inspection.

Implementation Approach

Implementation Approach

Understanding Rejection Criteria: InovarTech worked closely with the client to understand their specific quality requirements, including the critical rejection criteria of detecting particles as small as 0.15 microns.

Understanding Rejection Criteria: InovarTech worked closely with the client to understand their specific quality requirements, including the critical rejection criteria of detecting particles as small as 0.15 microns.

Understanding Rejection Criteria: InovarTech worked closely with the client to understand their specific quality requirements, including the critical rejection criteria of detecting particles as small as 0.15 microns.

Optimized Hardware Setup: Appropriate IP cameras were installed to capture high-resolution images of vials and ampules against both white and black backgrounds.

Optimized Hardware Setup: Appropriate IP cameras were installed to capture high-resolution images of vials and ampules against both white and black backgrounds.

Optimized Hardware Setup: Appropriate IP cameras were installed to capture high-resolution images of vials and ampules against both white and black backgrounds.

Custom AI/ML Algorithm Development: InovarTech developed a custom AI/ML algorithm using computer vision and pattern recognition techniques to accurately detect foreign particles and defects, even in varying sizes and shapes of vials and ampules.

Custom AI/ML Algorithm Development: InovarTech developed a custom AI/ML algorithm using computer vision and pattern recognition techniques to accurately detect foreign particles and defects, even in varying sizes and shapes of vials and ampules.

Custom AI/ML Algorithm Development: InovarTech developed a custom AI/ML algorithm using computer vision and pattern recognition techniques to accurately detect foreign particles and defects, even in varying sizes and shapes of vials and ampules.

Seamless Integration: VisionGuard was integrated with the client's existing production line and quality control systems for a streamlined workflow.

Seamless Integration: VisionGuard was integrated with the client's existing production line and quality control systems for a streamlined workflow.

Seamless Integration: VisionGuard was integrated with the client's existing production line and quality control systems for a streamlined workflow.

Key Capabilities

Key Capabilities

Automated Visual Inspection: VisionGuard automatically inspected vials and ampules, eliminating the need for manual inspection.

Automated Visual Inspection: VisionGuard automatically inspected vials and ampules, eliminating the need for manual inspection.

Automated Visual Inspection: VisionGuard automatically inspected vials and ampules, eliminating the need for manual inspection.

High Accuracy: The AI-powered system surpassed human capabilities in detecting foreign particles and defects, ensuring consistent and reliable quality control.

High Accuracy: The AI-powered system surpassed human capabilities in detecting foreign particles and defects, ensuring consistent and reliable quality control.

High Accuracy: The AI-powered system surpassed human capabilities in detecting foreign particles and defects, ensuring consistent and reliable quality control.

Real-time Reporting: VisionGuard generated real-time reports on inspection results, providing valuable insights into quality trends and potential issues.

Real-time Reporting: VisionGuard generated real-time reports on inspection results, providing valuable insights into quality trends and potential issues.

Real-time Reporting: VisionGuard generated real-time reports on inspection results, providing valuable insights into quality trends and potential issues.

Reduced Manual Errors: The automated system minimized manual errors and inconsistencies, improving the overall quality of the inspection process.

Reduced Manual Errors: The automated system minimized manual errors and inconsistencies, improving the overall quality of the inspection process.

Reduced Manual Errors: The automated system minimized manual errors and inconsistencies, improving the overall quality of the inspection process.

The Results: A Clear Vision for Quality Improvement

The Results: A Clear Vision for Quality Improvement

The Results: A Clear Vision for Quality Improvement

The Results: A Clear Vision for Quality Improvement

The implementation of VisionGuard delivered significant benefits:

The implementation of VisionGuard delivered significant benefits:

The implementation of VisionGuard delivered significant benefits:

Enhanced Accuracy: The AI-powered system significantly improved the accuracy of foreign particle and defect detection, exceeding human capabilities and mitigating the risk of adverse drug reactions.

Enhanced Accuracy: The AI-powered system significantly improved the accuracy of foreign particle and defect detection, exceeding human capabilities and mitigating the risk of adverse drug reactions.

Enhanced Accuracy: The AI-powered system significantly improved the accuracy of foreign particle and defect detection, exceeding human capabilities and mitigating the risk of adverse drug reactions.

Increased Efficiency: Automated inspection streamlined the quality assurance process, reducing processing time and increasing throughput.

Increased Efficiency: Automated inspection streamlined the quality assurance process, reducing processing time and increasing throughput.

Increased Efficiency: Automated inspection streamlined the quality assurance process, reducing processing time and increasing throughput.

Cost Savings: By reducing the need for manual labor, VisionGuard delivered significant cost savings in terms of labor and operational expenses.

Cost Savings: By reducing the need for manual labor, VisionGuard delivered significant cost savings in terms of labor and operational expenses.

Cost Savings: By reducing the need for manual labor, VisionGuard delivered significant cost savings in terms of labor and operational expenses.

Improved Quality Control: Real-time reporting and data analysis enabled proactive identification and resolution of quality issues, leading to enhanced quality control.

Improved Quality Control: Real-time reporting and data analysis enabled proactive identification and resolution of quality issues, leading to enhanced quality control.

Improved Quality Control: Real-time reporting and data analysis enabled proactive identification and resolution of quality issues, leading to enhanced quality control.

Brand Protection: By ensuring the highest quality standards, VisionGuard helped protect the client's brand reputation and mitigate the risk of legal and compliance issues.

Brand Protection: By ensuring the highest quality standards, VisionGuard helped protect the client's brand reputation and mitigate the risk of legal and compliance issues.

Brand Protection: By ensuring the highest quality standards, VisionGuard helped protect the client's brand reputation and mitigate the risk of legal and compliance issues.

“

“

"VisionGuard has not only transformed our quality assurance process but also provided us with peace of mind knowing that we are minimizing the risk of potentially harmful foreign particles in our products.

The accuracy and efficiency of the system have exceeded our expectations, and we have seen a significant improvement in our overall quality control.”

"I set up a consultation and was blown away by how professional and helpful my advisor was. Highly recommend this service to everyone."

"VisionGuard has not only transformed our quality assurance process but also provided us with peace of mind knowing that we are minimizing the risk of potentially harmful foreign particles in our products.

The accuracy and efficiency of the system have exceeded our expectations, and we have seen a significant improvement in our overall quality control.”

Shrikant Gandhe

Shrikant Gandhe

Shrikant Gandhe

Shrikant Gandhe

VP-Quality Assurance

VP-Quality Assurance

VP-Quality Assurance

VP-Quality Assurance

The Future:

Enhancing Quality and Efficiency with AI Vision

The Future:

Enhancing Quality and Efficiency with AI Vision

The Future:

Enhancing Quality and Efficiency with AI Vision

This implementation showcases the power of AI vision to transform quality assurance in the pharmaceutical industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

This implementation showcases the power of AI vision to transform quality assurance in the pharmaceutical industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

This implementation showcases the power of AI vision to transform quality assurance in the pharmaceutical industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

Ensure the highest quality standards for pharmaceutical products

Ensure the highest quality standards for pharmaceutical products

Ensure the highest quality standards for pharmaceutical products

Reduce costs and improve productivity

Reduce costs and improve productivity

Reduce costs and improve productivity

Drive innovation and adopt advanced manufacturing techniques

Drive innovation and adopt advanced manufacturing techniques

Drive innovation and adopt advanced manufacturing techniques

Protect brand reputation and mitigate risks to patient safety

Protect brand reputation and mitigate risks to patient safety

Protect brand reputation and mitigate risks to patient safety

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering pharmaceutical companies to achieve new levels of quality and efficiency in their manufacturing processes.

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering pharmaceutical companies to achieve new levels of quality and efficiency in their manufacturing processes.

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering pharmaceutical companies to achieve new levels of quality and efficiency in their manufacturing processes.

More Case Studies

Omni-Channel Retailer Reduces Tickets, Boosts Loyalty.

InovarTech assisted a leading lab in overcoming its data management challenges by equipping them with an efficient process automation platform for managing work orders seamlessly.

Saudi oil manufacturer boosts Food safety

with AI inspection.

Multi-national achieves product excellence with AI.

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved