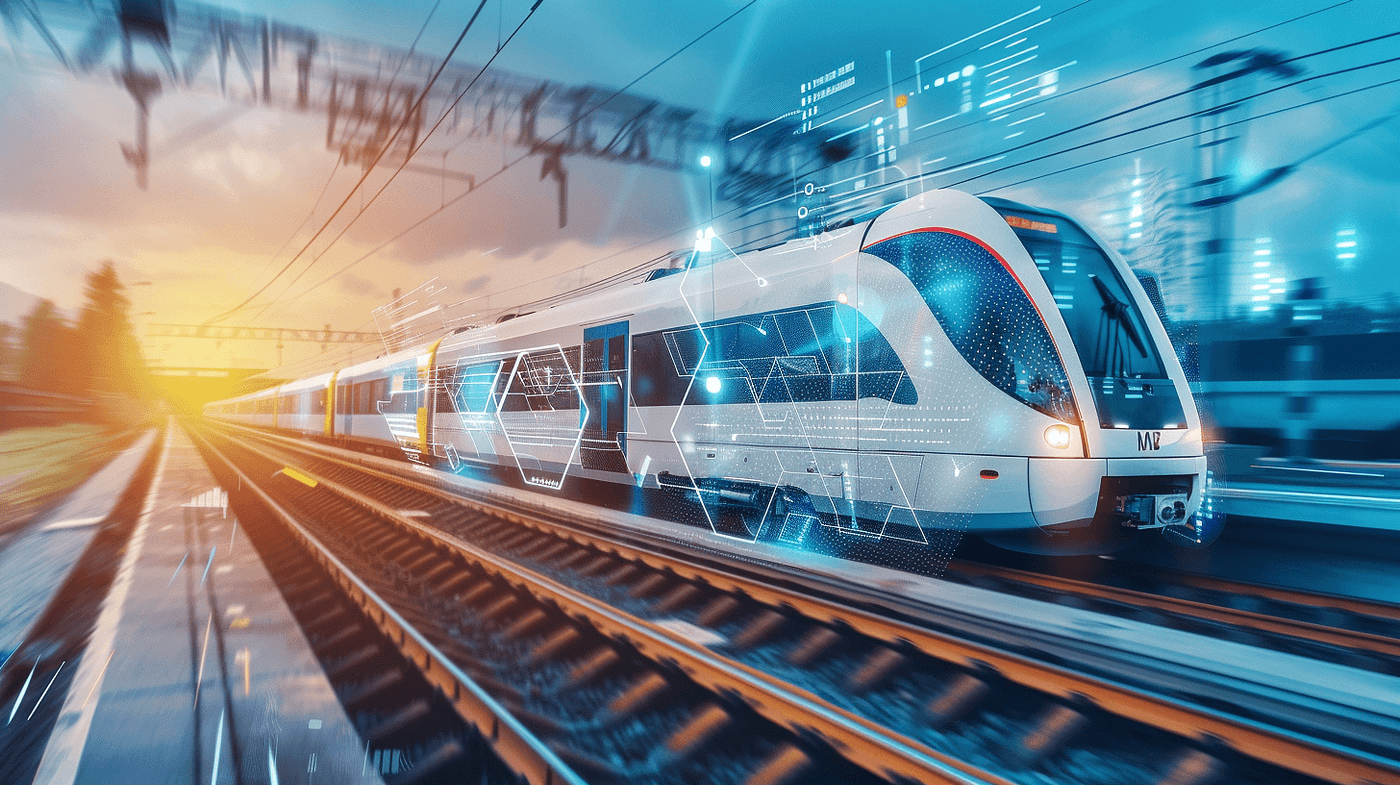

Revolutionizing Indian Railways with AI-Powered Predictive Maintenance: Ensuring Efficiency for the World's 4th Largest Network

Revolutionizing Indian Railways with AI-Powered Predictive Maintenance: Ensuring Efficiency for the World's 4th Largest Network

Revolutionizing Indian Railways with AI-Powered Predictive Maintenance: Ensuring Efficiency for the World's 4th Largest Network

Revolutionizing Indian Railways with AI-Powered Predictive Maintenance: Ensuring Efficiency for the World's 4th Largest Network

Challenge: A major government railway network, operating one of the world's largest and most complex rail systems, sought to improve the safety, reliability, and efficiency of its electric locomotive fleet. Traditional maintenance practices proved reactive and costly, leading to unplanned downtime and disruptions.

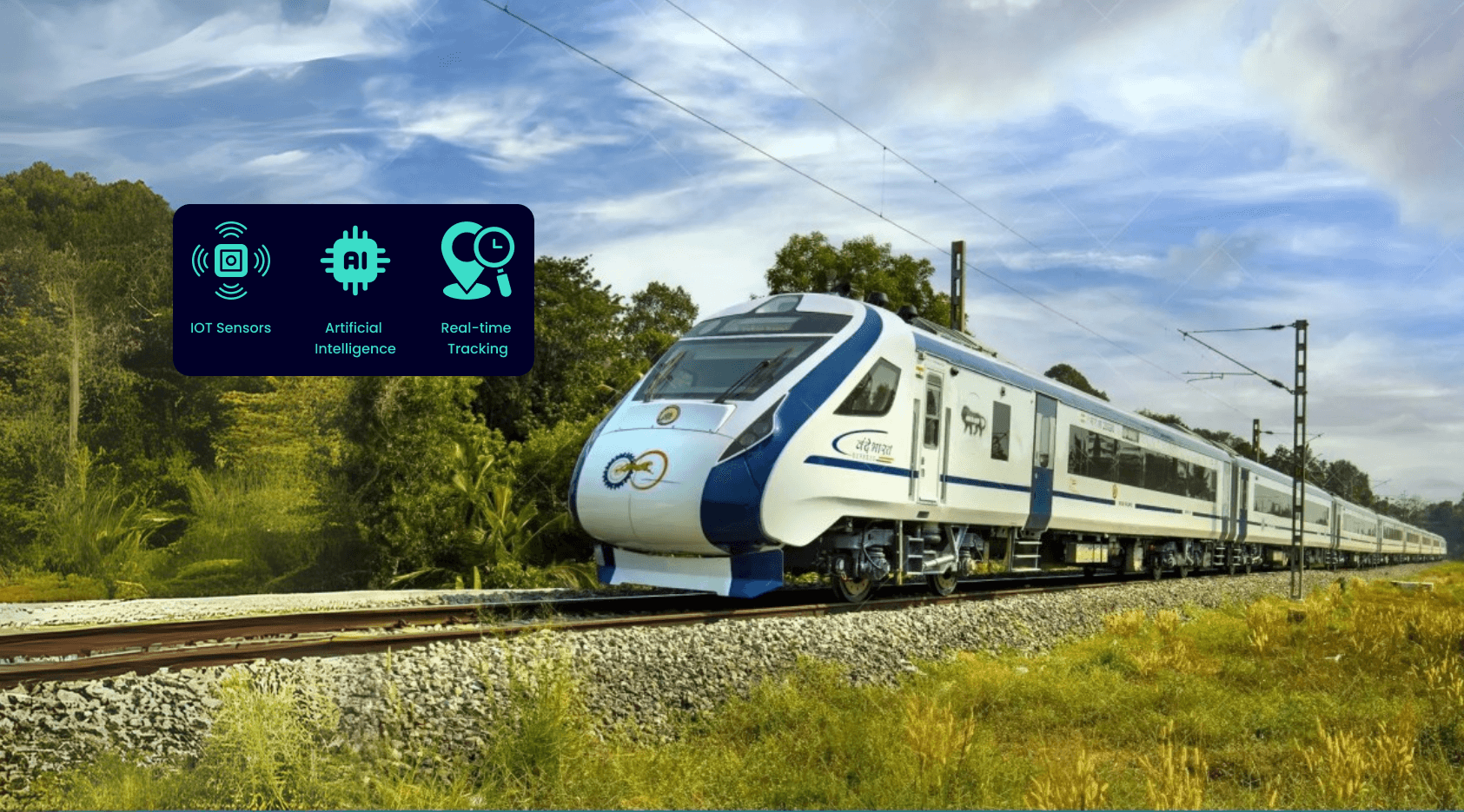

Solution: InovarTech leveraged its Gen AI and predictive AI capabilities to develop a cutting-edge Predictive Maintenance System (IRPMS). This solution integrates IoT sensors, machine learning, and advanced analytics to provide real-time locomotive health monitoring, failure prediction, and optimized maintenance scheduling.

Results: The IRPMS delivered significant improvements, including a 15% increase in locomotive uptime, a 20% reduction in maintenance costs, a 10% reduction in safety-related incidents, and a 5% improvement in overall operational efficiency, resulting in a strong ROI for the railway network.

Challenge: A major government railway network, operating one of the world's largest and most complex rail systems, sought to improve the safety, reliability, and efficiency of its electric locomotive fleet. Traditional maintenance practices proved reactive and costly, leading to unplanned downtime and disruptions.

Solution: InovarTech leveraged its Gen AI and predictive AI capabilities to develop a cutting-edge Predictive Maintenance System (IRPMS). This solution integrates IoT sensors, machine learning, and advanced analytics to provide real-time locomotive health monitoring, failure prediction, and optimized maintenance scheduling.

Results: The IRPMS delivered significant improvements, including a 15% increase in locomotive uptime, a 20% reduction in maintenance costs, a 10% reduction in safety-related incidents, and a 5% improvement in overall operational efficiency, resulting in a strong ROI for the railway network.

Client: A leading Omni-channel fashion retailer with 600+ stores from South Asia.

Challenge: Inefficient support operations burdened by high ticket volume, diverse incidents, and rising customer dissatisfaction.

Solution: InovarTech's Agentic AI-powered Self-Service Agent platform, leveraging Microsoft Copilot Studio.

Results: 30% reduction in support tickets, significant decrease in escalations, 15% growth in repeat business, and enhanced customer loyalty.

Challenge: A major government railway network, operating one of the world's largest and most complex rail systems, sought to improve the safety, reliability, and efficiency of its electric locomotive fleet. Traditional maintenance practices proved reactive and costly, leading to unplanned downtime and disruptions.

Solution: InovarTech leveraged its Gen AI and predictive AI capabilities to develop a cutting-edge Predictive Maintenance System (IRPMS). This solution integrates IoT sensors, machine learning, and advanced analytics to provide real-time locomotive health monitoring, failure prediction, and optimized maintenance scheduling.

Results: The IRPMS delivered significant improvements, including a 15% increase in locomotive uptime, a 20% reduction in maintenance costs, a 10% reduction in safety-related incidents, and a 5% improvement in overall operational efficiency, resulting in a strong ROI for the railway network.

Challenge: A major government railway network, operating one of the world's largest and most complex rail systems, sought to improve the safety, reliability, and efficiency of its electric locomotive fleet. Traditional maintenance practices proved reactive and costly, leading to unplanned downtime and disruptions.

Solution: InovarTech leveraged its Gen AI and predictive AI capabilities to develop a cutting-edge Predictive Maintenance System (IRPMS). This solution integrates IoT sensors, machine learning, and advanced analytics to provide real-time locomotive health monitoring, failure prediction, and optimized maintenance scheduling.

Results: The IRPMS delivered significant improvements, including a 15% increase in locomotive uptime, a 20% reduction in maintenance costs, a 10% reduction in safety-related incidents, and a 5% improvement in overall operational efficiency, resulting in a strong ROI for the railway network.

Machine Learning

Machine Learning

Machine Learning

Rail Operations

Rail Operations

Rail Operations

Locomotive

Locomotive

Locomotive

Gen AI

Gen AI

Gen AI

Predictive Maintenance

Predictive Maintenance

Predictive Maintenance

Cost Reduction

Cost Reduction

Cost Reduction

The Challenge: Maintaining Complex Railway Operations at Scale

The Challenge: Maintaining Complex Railway Operations at Scale

The Challenge: Maintaining Complex Railway Operations at Scale

Managing a vast fleet of electric locomotives across diverse terrains presents significant operational challenges:

Managing a vast fleet of electric locomotives across diverse terrains presents significant operational challenges:

Managing a vast fleet of electric locomotives across diverse terrains presents significant operational challenges:

Reactive Maintenance: Traditional maintenance approaches rely on scheduled inspections and react to failures, leading to unexpected downtime, costly repairs, and operational disruptions.

Reactive Maintenance: Traditional maintenance approaches rely on scheduled inspections and react to failures, leading to unexpected downtime, costly repairs, and operational disruptions.

Limited Visibility: Lack of real-time insights into locomotive health hinders proactive decision-making and efficient resource allocation.

Limited Visibility: Lack of real-time insights into locomotive health hinders proactive decision-making and efficient resource allocation.

Complex Data Management: The sheer volume and complexity of data generated by locomotives require sophisticated analysis and interpretation to extract actionable insights.

Complex Data Management: The sheer volume and complexity of data generated by locomotives require sophisticated analysis and interpretation to extract actionable insights.

The InovarTech Solution

The InovarTech Solution

The InovarTech Solution

Gen AI and Predictive AI for Optimized Maintenance

Gen AI and Predictive AI for Optimized Maintenance

Gen AI and Predictive AI for Optimized Maintenance

InovarTech's IRPMS solution addresses these challenges by harnessing the power of Gen AI and predictive AI:

InovarTech's IRPMS solution addresses these challenges by harnessing the power of Gen AI and predictive AI:

InovarTech's IRPMS solution addresses these challenges by harnessing the power of Gen AI and predictive AI:

IoT Sensors and Data Acquisition: Advanced IoT sensors deployed on locomotives capture real-time data on critical parameters (voltage, current, temperature, vibration, etc.), providing a continuous stream of performance information.

IoT Sensors and Data Acquisition: Advanced IoT sensors deployed on locomotives capture real-time data on critical parameters (voltage, current, temperature, vibration, etc.), providing a continuous stream of performance information.

AI-Driven Predictive Analytics: Our proprietary machine learning algorithms analyze sensor data to identify patterns, predict potential equipment failures, and prescribe optimal maintenance schedules.

AI-Driven Predictive Analytics: Our proprietary machine learning algorithms analyze sensor data to identify patterns, predict potential equipment failures, and prescribe optimal maintenance schedules.

Real-time Tracking and Visualization: GPS and tracking technologies provide real-time location data, visualized on interactive dashboards for enhanced operational visibility and fleet management.

Real-time Tracking and Visualization: GPS and tracking technologies provide real-time location data, visualized on interactive dashboards for enhanced operational visibility and fleet management.

Seamless System Integration: The IRPMS seamlessly integrates with existing railway systems, including legacy databases and maintenance management software, for a unified data platform.

Seamless System Integration: The IRPMS seamlessly integrates with existing railway systems, including legacy databases and maintenance management software, for a unified data platform.

The Results: Delivering Tangible Business Value

The Results: Delivering Tangible Business Value

The Results: Delivering Tangible Business Value

The Results: Delivering Tangible Business Value

The AI-powered IRPMS solution delivered substantial benefits:

The AI-powered IRPMS solution delivered substantial benefits:

The AI-powered IRPMS solution delivered substantial benefits:

Increased Uptime and Availability: Predictive maintenance reduced unplanned downtime by 15%, increasing locomotive availability and operational efficiency.

Increased Uptime and Availability: Predictive maintenance reduced unplanned downtime by 15%, increasing locomotive availability and operational efficiency.

Reduced Maintenance Costs: Proactive maintenance optimized maintenance schedules and minimized costly repairs, resulting in a 20% reduction in maintenance costs.

Reduced Maintenance Costs: Proactive maintenance optimized maintenance schedules and minimized costly repairs, resulting in a 20% reduction in maintenance costs.

Enhanced Safety: Real-time monitoring and predictive maintenance improved operational safety, leading to a 10% reduction in safety-related incidents.

Enhanced Safety: Real-time monitoring and predictive maintenance improved operational safety, leading to a 10% reduction in safety-related incidents.

Improved Decision-Making: The IRPMS empowered railway personnel with data-driven insights for informed decision-making, resource optimization, and strategic planning, resulting in a 5% improvement in overall operational efficiency.

Improved Decision-Making: The IRPMS empowered railway personnel with data-driven insights for informed decision-making, resource optimization, and strategic planning, resulting in a 5% improvement in overall operational efficiency.

“

“

The IRPMS has revolutionized our maintenance operations. We've significantly reduced downtime, optimized maintenance spend, and improved the safety of our railway network. InovarTech's AI-powered solution has been a game-changer.

"I set up a consultation and was blown away by how professional and helpful my advisor was. Highly recommend this service to everyone."

The IRPMS has revolutionized our maintenance operations. We've significantly reduced downtime, optimized maintenance spend, and improved the safety of our railway network. InovarTech's AI-powered solution has been a game-changer.

The IRPMS has revolutionized our maintenance operations. We've significantly reduced downtime, optimized maintenance spend, and improved the safety of our railway network. InovarTech's AI-powered solution has been a game-changer.

R Santhosh

R Santhosh

R Santhosh

R Santhosh

Director Operations - Electric Locomotive Division, South Central Zone, Indian Railways

Director Operations - Electric Locomotive Division, South Central Zone, Indian Railways

Director Operations - Electric Locomotive Division, South Central Zone, Indian Railways

Director Operations - Electric Locomotive Division, South Central Zone, Indian Railways

The Future: AI-Driven Transformation for the Railway Industry

The Future: AI-Driven Transformation for the Railway Industry

The Future: AI-Driven Transformation for the Railway Industry

InovarTech is committed to empowering railway networks worldwide with innovative AI solutions. By leveraging Gen AI and predictive AI, railway organizations can:

InovarTech is committed to empowering railway networks worldwide with innovative AI solutions. By leveraging Gen AI and predictive AI, railway organizations can:

InovarTech is committed to empowering railway networks worldwide with innovative AI solutions. By leveraging Gen AI and predictive AI, railway organizations can:

Drive operational efficiency and cost reductions.

Drive operational efficiency and cost reductions.

Drive operational efficiency and cost reductions.

Enhance the safety and reliability of services.

Enhance the safety and reliability of services.

Enhance the safety and reliability of services.

Optimize resource allocation and maintenance strategies.

Optimize resource allocation and maintenance strategies.

Optimize resource allocation and maintenance strategies.

Gain valuable data-driven insights for strategic decision-making.

Gain valuable data-driven insights for strategic decision-making.

Gain valuable data-driven insights for strategic decision-making.

InovarTech, in partnership with Microsoft AI Technologies, is at the forefront of this transformation, empowering retailers to deliver exceptional customer experiences in the age of hyper-connectivity.

InovarTech, in partnership with Microsoft AI Technologies, is at the forefront of this transformation, empowering retailers to deliver exceptional customer experiences in the age of hyper-connectivity.

InovarTech, in partnership with Microsoft AI Technologies, is at the forefront of this transformation, empowering retailers to deliver exceptional customer experiences in the age of hyper-connectivity.

Contact InovarTech today to explore how our AI solutions can transform your railway operations.

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved