Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Client: A leading cooking oil manufacturer in Saudi Arabia and the MENA region with a strong portfolio of brands and a commitment to innovation since 1979. The company has achieved market leadership with its brands and is actively pursuing expansion and diversification in the food sector.

Challenge: Manual visual inspection of cooking oil bottles for foreign particles was labor-intensive, prone to errors, and posed risks to product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality control.

Results:

Client: A leading cooking oil manufacturer in Saudi Arabia and the MENA region with a strong portfolio of brands and a commitment to innovation since 1979. The company has achieved market leadership with its brands and is actively pursuing expansion and diversification in the food sector.

Challenge: Manual visual inspection of cooking oil bottles for foreign particles was labor-intensive, prone to errors, and posed risks to product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality control.

Results:

Client: A leading cooking oil manufacturer in Saudi Arabia and the MENA region with a strong portfolio of brands and a commitment to innovation since 1979. The company has achieved market leadership with its brands and is actively pursuing expansion and diversification in the food sector.

Challenge: Manual visual inspection of cooking oil bottles for foreign particles was labor-intensive, prone to errors, and posed risks to product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality control.

Results:

Client: A leading cooking oil manufacturer in Saudi Arabia and the MENA region with a strong portfolio of brands and a commitment to innovation since 1979. The company has achieved market leadership with its brands and is actively pursuing expansion and diversification in the food sector.

Challenge: Manual visual inspection of cooking oil bottles for foreign particles was labor-intensive, prone to errors, and posed risks to product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality control.

Results:

Client: A leading cooking oil manufacturer in Saudi Arabia and the MENA region with a strong portfolio of brands and a commitment to innovation since 1979. The company has achieved market leadership with its brands and is actively pursuing expansion and diversification in the food sector.

Challenge: Manual visual inspection of cooking oil bottles for foreign particles was labor-intensive, prone to errors, and posed risks to product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate the visual inspection process and enhance quality control.

Results:

Improved Accuracy: Increased foreign particle detection rates by 15%, minimizing the risk of contaminated products reaching consumers.

Improved Accuracy: Increased foreign particle detection rates by 15%, minimizing the risk of contaminated products reaching consumers.

Improved Accuracy: Increased foreign particle detection rates by 15%, minimizing the risk of contaminated products reaching consumers.

Increased Efficiency: Reduced manual inspection labor by 60%, allowing for redeployment of staff to higher-value tasks.

Increased Efficiency: Reduced manual inspection labor by 60%, allowing for redeployment of staff to higher-value tasks.

Increased Efficiency: Reduced manual inspection labor by 60%, allowing for redeployment of staff to higher-value tasks.

Cost Savings: Achieved an estimated annual cost savings of $200,000 through reduced labor costs and minimized product waste.

Cost Savings: Achieved an estimated annual cost savings of $200,000 through reduced labor costs and minimized product waste.

Cost Savings: Achieved an estimated annual cost savings of $200,000 through reduced labor costs and minimized product waste.

Enhanced Brand Protection: Strengthened brand reputation and consumer trust by ensuring product purity and safety.

Enhanced Brand Protection: Strengthened brand reputation and consumer trust by ensuring product purity and safety.

Enhanced Brand Protection: Strengthened brand reputation and consumer trust by ensuring product purity and safety.

Food Safety

Food Safety

Food Safety

Cooking Oil

Cooking Oil

Cooking Oil

Automated Inspection

Automated Inspection

Automated Inspection

AI Vision

AI Vision

AI Vision

Saudi Arabia

Saudi Arabia

Saudi Arabia

VisionGuard

VisionGuard

VisionGuard

The Challenge:

Ensuring Purity in Cooking Oil Production

The Challenge:

Ensuring Purity in Cooking Oil Production

The Challenge:

Ensuring Purity in Cooking Oil Production

Maintaining the highest standards of purity and quality in cooking oil production is essential for consumer safety and brand reputation. This leading cooking oil manufacturer faced challenges in their quality assurance process due to the presence of foreign particles in their bottled cooking oil.

Maintaining the highest standards of purity and quality in cooking oil production is essential for consumer safety and brand reputation. This leading cooking oil manufacturer faced challenges in their quality assurance process due to the presence of foreign particles in their bottled cooking oil.

Maintaining the highest standards of purity and quality in cooking oil production is essential for consumer safety and brand reputation. This leading cooking oil manufacturer faced challenges in their quality assurance process due to the presence of foreign particles in their bottled cooking oil.

Manual Inspection: 50 employees worked in 3 shifts to visually inspect filled cooking oil bottles for foreign particles, a process that was labor-intensive, prone to human error, and potentially inconsistent.

Manual Inspection: 50 employees worked in 3 shifts to visually inspect filled cooking oil bottles for foreign particles, a process that was labor-intensive, prone to human error, and potentially inconsistent.

Manual Inspection: 50 employees worked in 3 shifts to visually inspect filled cooking oil bottles for foreign particles, a process that was labor-intensive, prone to human error, and potentially inconsistent.

Black Particle Contamination: One of the main issues was the presence of small black particles inside the bottles. These particles likely originated from the plastic bottle manufacturing process (using preforms) and were introduced during the filling process due to factors such as:

Black Particle Contamination: One of the main issues was the presence of small black particles inside the bottles. These particles likely originated from the plastic bottle manufacturing process (using preforms) and were introduced during the filling process due to factors such as:

Black Particle Contamination: One of the main issues was the presence of small black particles inside the bottles. These particles likely originated from the plastic bottle manufacturing process (using preforms) and were introduced during the filling process due to factors such as:

Degradation of the preform material: High temperatures during the preform injection molding process or storage can cause degradation, leading to black particles.

Degradation of the preform material: High temperatures during the preform injection molding process or storage can cause degradation, leading to black particles.

Degradation of the preform material: High temperatures during the preform injection molding process or storage can cause degradation, leading to black particles.

Contamination in the preform mold: Residual particles or debris in the mold can contaminate the preforms.

Contamination in the preform mold: Residual particles or debris in the mold can contaminate the preforms.

Contamination in the preform mold: Residual particles or debris in the mold can contaminate the preforms.

Improper handling or storage of preforms: Dust, debris, or other contaminants can settle on preforms during storage or transportation.

Improper handling or storage of preforms: Dust, debris, or other contaminants can settle on preforms during storage or transportation.

Improper handling or storage of preforms: Dust, debris, or other contaminants can settle on preforms during storage or transportation.

Brand Risk: The presence of foreign particles in cooking oil poses a significant risk to consumer health and can severely damage brand reputation and consumer trust.

Brand Risk: The presence of foreign particles in cooking oil poses a significant risk to consumer health and can severely damage brand reputation and consumer trust.

Brand Risk: The presence of foreign particles in cooking oil poses a significant risk to consumer health and can severely damage brand reputation and consumer trust.

The Solution

The Solution

The Solution

VisionGuard – An AI-Powered Eye for Purity

VisionGuard – An AI-Powered Eye for Purity

VisionGuard – An AI-Powered Eye for Purity

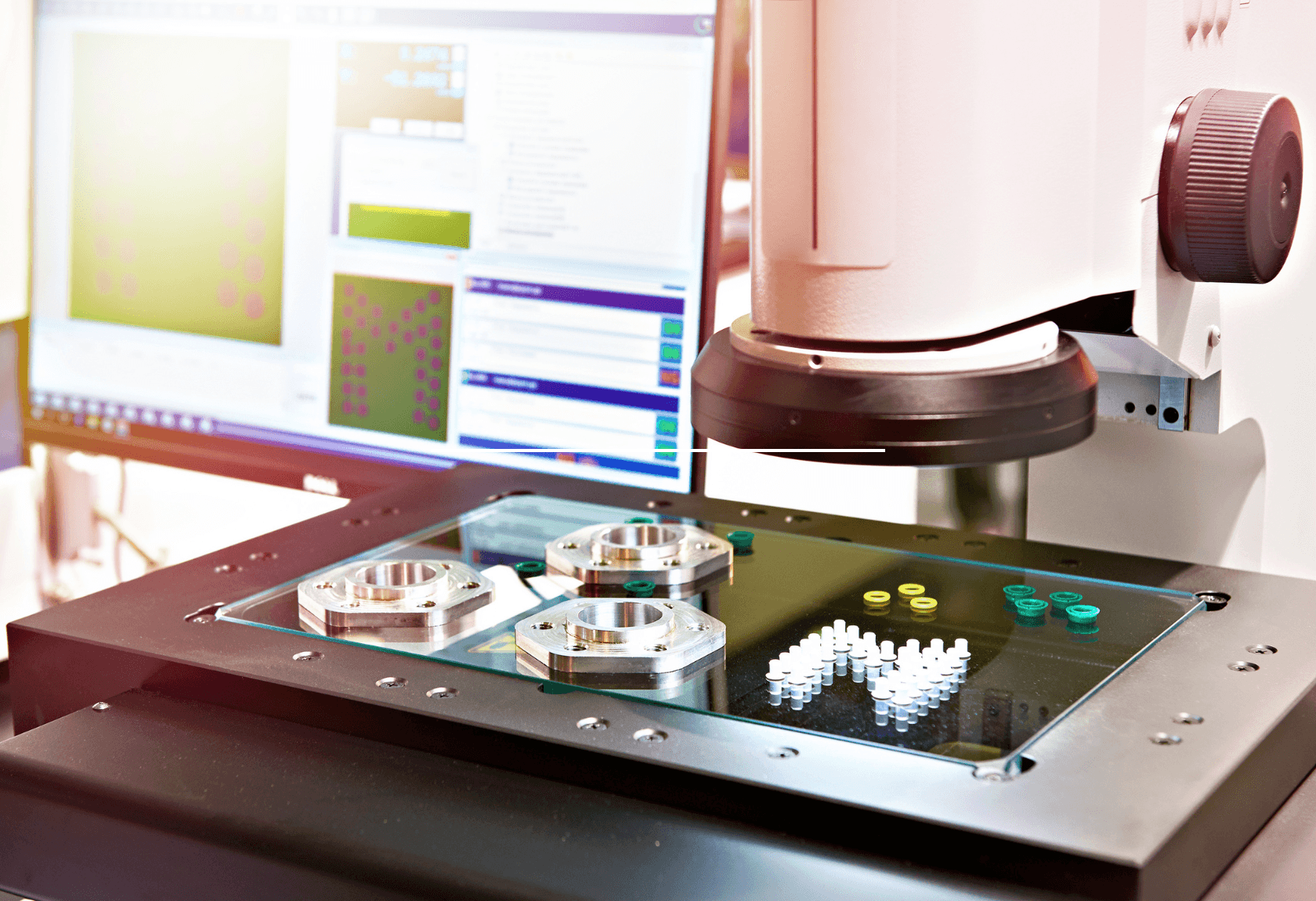

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the cooking oil manufacturer's quality assurance process and mitigate the risks associated with foreign particle contamination.

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the cooking oil manufacturer's quality assurance process and mitigate the risks associated with foreign particle contamination.

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the cooking oil manufacturer's quality assurance process and mitigate the risks associated with foreign particle contamination.

Implementation Approach

Implementation Approach

Collaboration and Understanding: InovarTech worked closely with the manufacturer's production and quality teams to understand their specific requirements, challenges, and the potential sources of contamination.

Collaboration and Understanding: InovarTech worked closely with the manufacturer's production and quality teams to understand their specific requirements, challenges, and the potential sources of contamination.

Collaboration and Understanding: InovarTech worked closely with the manufacturer's production and quality teams to understand their specific requirements, challenges, and the potential sources of contamination.

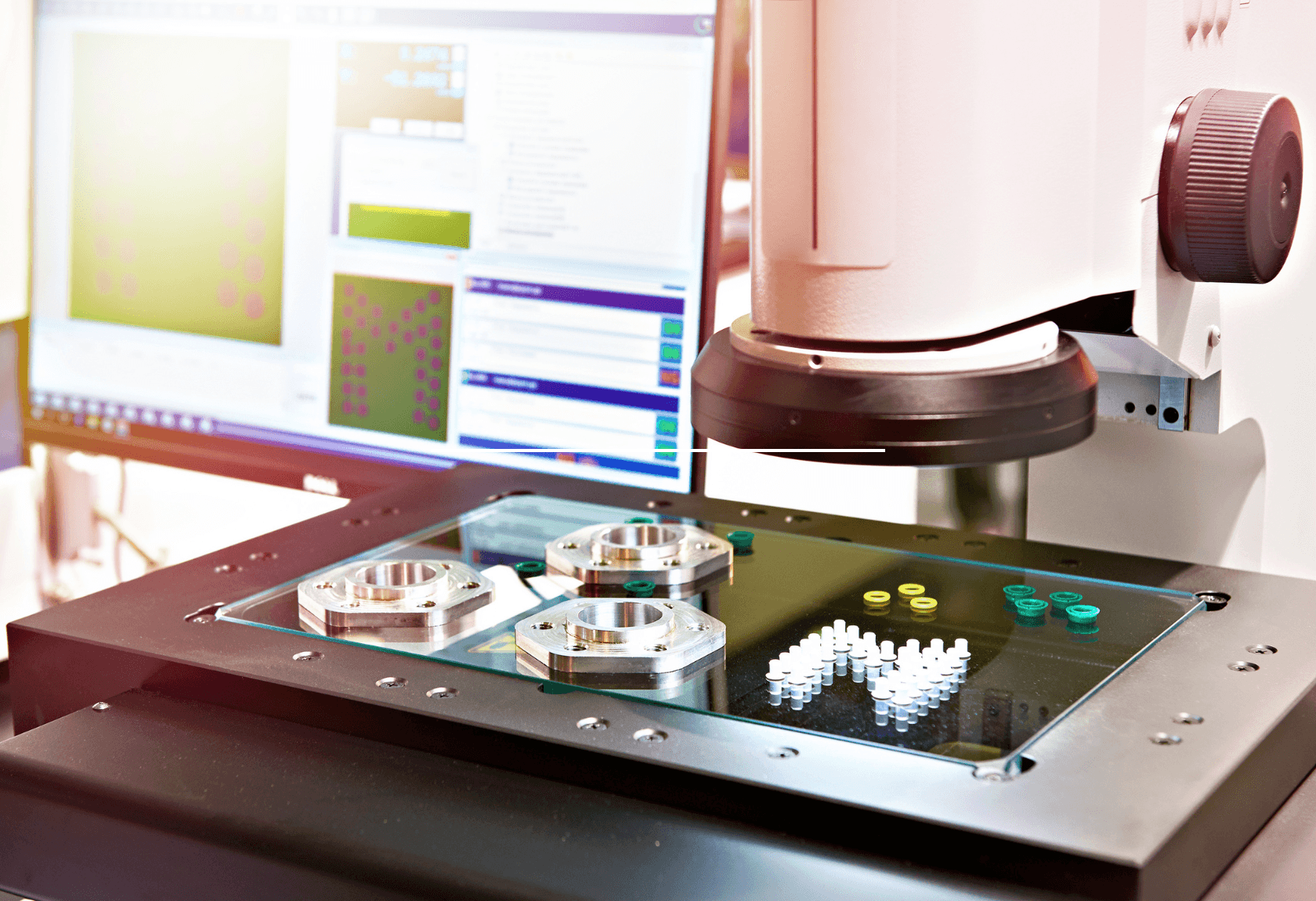

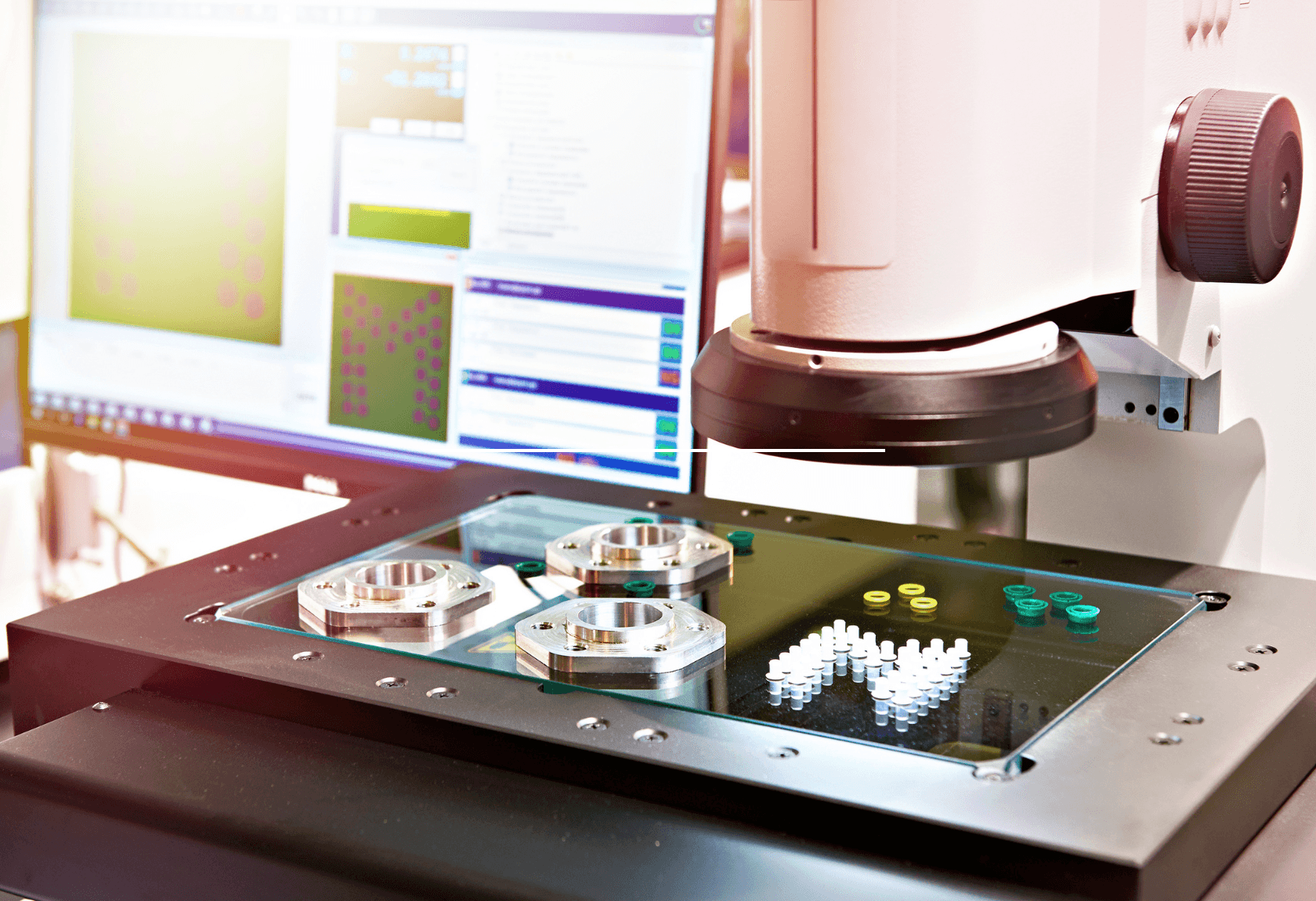

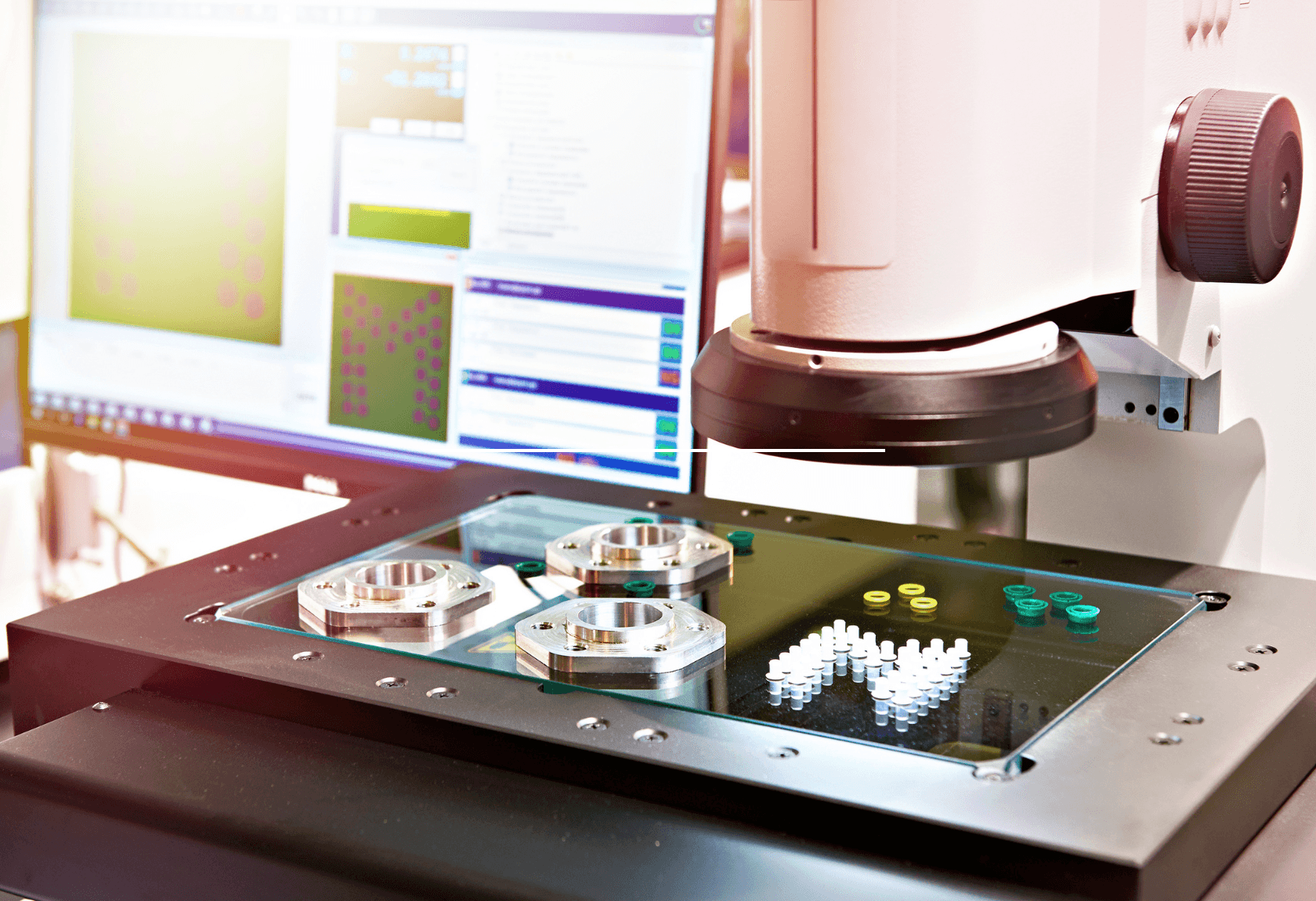

Optimized Hardware Setup: High-resolution cameras and lighting systems were installed on the production lines to capture clear images of the cooking oil bottles during the filling process.

Optimized Hardware Setup: High-resolution cameras and lighting systems were installed on the production lines to capture clear images of the cooking oil bottles during the filling process.

Optimized Hardware Setup: High-resolution cameras and lighting systems were installed on the production lines to capture clear images of the cooking oil bottles during the filling process.

Custom AI/ML Algorithm Development: InovarTech developed a custom AI/ML algorithm using computer vision and pattern recognition techniques to accurately detect foreign particles, including the small black particles, in the cooking oil bottles.

Custom AI/ML Algorithm Development: InovarTech developed a custom AI/ML algorithm using computer vision and pattern recognition techniques to accurately detect foreign particles, including the small black particles, in the cooking oil bottles.

Custom AI/ML Algorithm Development: InovarTech developed a custom AI/ML algorithm using computer vision and pattern recognition techniques to accurately detect foreign particles, including the small black particles, in the cooking oil bottles.

Seamless Integration: VisionGuard was integrated with the manufacturer's existing production line and quality control systems for a streamlined workflow.

Seamless Integration: VisionGuard was integrated with the manufacturer's existing production line and quality control systems for a streamlined workflow.

Seamless Integration: VisionGuard was integrated with the manufacturer's existing production line and quality control systems for a streamlined workflow.

Key Capabilities

Key Capabilities

Automated Visual Inspection: VisionGuard automatically inspected cooking oil bottles for foreign particles, eliminating the need for manual inspection.

Automated Visual Inspection: VisionGuard automatically inspected cooking oil bottles for foreign particles, eliminating the need for manual inspection.

Automated Visual Inspection: VisionGuard automatically inspected cooking oil bottles for foreign particles, eliminating the need for manual inspection.

High Accuracy: The AI-powered system surpassed human capabilities in detecting foreign particles, ensuring consistent and reliable quality control.

High Accuracy: The AI-powered system surpassed human capabilities in detecting foreign particles, ensuring consistent and reliable quality control.

High Accuracy: The AI-powered system surpassed human capabilities in detecting foreign particles, ensuring consistent and reliable quality control.

Real-time Alerts: VisionGuard triggered real-time alerts when foreign particles were detected, allowing for immediate corrective action and preventing contaminated products from reaching consumers.

Real-time Alerts: VisionGuard triggered real-time alerts when foreign particles were detected, allowing for immediate corrective action and preventing contaminated products from reaching consumers.

Real-time Alerts: VisionGuard triggered real-time alerts when foreign particles were detected, allowing for immediate corrective action and preventing contaminated products from reaching consumers.

Reduced Manual Errors: The automated system minimized manual errors and inconsistencies, improving the overall quality of the inspection process.

Reduced Manual Errors: The automated system minimized manual errors and inconsistencies, improving the overall quality of the inspection process.

Reduced Manual Errors: The automated system minimized manual errors and inconsistencies, improving the overall quality of the inspection process.

The Results: Protecting Purity and Brand Reputation

The Results: Protecting Purity and Brand Reputation

The Results: Protecting Purity and Brand Reputation

The Results: Protecting Purity and Brand Reputation

The implementation of VisionGuard delivered significant benefits:

The implementation of VisionGuard delivered significant benefits:

The implementation of VisionGuard delivered significant benefits:

Enhanced Accuracy: The AI-powered system significantly improved the accuracy of foreign particle detection, exceeding human capabilities and reducing the risk of contaminated products.

Enhanced Accuracy: The AI-powered system significantly improved the accuracy of foreign particle detection, exceeding human capabilities and reducing the risk of contaminated products.

Enhanced Accuracy: The AI-powered system significantly improved the accuracy of foreign particle detection, exceeding human capabilities and reducing the risk of contaminated products.

Increased Efficiency: Automated inspection streamlined the quality assurance process, increasing production throughput and reducing labor costs.

Increased Efficiency: Automated inspection streamlined the quality assurance process, increasing production throughput and reducing labor costs.

Increased Efficiency: Automated inspection streamlined the quality assurance process, increasing production throughput and reducing labor costs.

Improved Quality Control: Real-time alerts and data analysis enabled proactive identification and resolution of quality issues, leading to enhanced quality control.

Improved Quality Control: Real-time alerts and data analysis enabled proactive identification and resolution of quality issues, leading to enhanced quality control.

Improved Quality Control: Real-time alerts and data analysis enabled proactive identification and resolution of quality issues, leading to enhanced quality control.

Brand Protection: By ensuring the highest standards of purity and safety, VisionGuard helped protect the manufacturer's brand reputation and maintain consumer trust.

Brand Protection: By ensuring the highest standards of purity and safety, VisionGuard helped protect the manufacturer's brand reputation and maintain consumer trust.

Brand Protection: By ensuring the highest standards of purity and safety, VisionGuard helped protect the manufacturer's brand reputation and maintain consumer trust.

“

“

Vision Guard has been instrumental in enhancing our quality control processes and protecting our brand reputation. The system's ability to accurately detect foreign particles and provide real-time alerts has given us confidence in the purity and safety of our products.

"I set up a consultation and was blown away by how professional and helpful my advisor was. Highly recommend this service to everyone."

Vision Guard has been instrumental in enhancing our quality control processes and protecting our brand reputation. The system's ability to accurately detect foreign particles and provide real-time alerts has given us confidence in the purity and safety of our products.

The Future:

AI-Powered Quality Assurance for Food Safety

The Future:

AI-Powered Quality Assurance for Food Safety

The Future:

AI-Powered Quality Assurance for Food Safety

This implementation showcases the power of AI vision to transform quality control in the food and beverage industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

This implementation showcases the power of AI vision to transform quality control in the food and beverage industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

This implementation showcases the power of AI vision to transform quality control in the food and beverage industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

Ensure the highest standards of food safety and quality

Ensure the highest standards of food safety and quality

Ensure the highest standards of food safety and quality

Protect brand reputation and build consumer trust

Protect brand reputation and build consumer trust

Protect brand reputation and build consumer trust

Optimize production processes and reduce costs

Optimize production processes and reduce costs

Optimize production processes and reduce costs

Drive innovation and adopt advanced manufacturing techniques

Drive innovation and adopt advanced manufacturing techniques

Drive innovation and adopt advanced manufacturing techniques

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering food and beverage companies to achieve new levels of quality and efficiency in their manufacturing processes.

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering food and beverage companies to achieve new levels of quality and efficiency in their manufacturing processes.

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering food and beverage companies to achieve new levels of quality and efficiency in their manufacturing processes.

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved