Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

Client: A pioneer and global leader in baby and child care brands and products, including diapers, wipes, and training pants.

Challenge: Manual quality assurance processes across 5 production lines were time-consuming, prone to inconsistencies, and limited in their ability to detect subtle defects, potentially impacting product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate visual inspection and enhance quality control across all production lines.

Results: Improved product consistency, reduced defect rates, enhanced brand reputation, and increased efficiency in quality assurance processes.

Client: A pioneer and global leader in baby and child care brands and products, including diapers, wipes, and training pants.

Challenge: Manual quality assurance processes across 5 production lines were time-consuming, prone to inconsistencies, and limited in their ability to detect subtle defects, potentially impacting product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate visual inspection and enhance quality control across all production lines.

Results: Improved product consistency, reduced defect rates, enhanced brand reputation, and increased efficiency in quality assurance processes.

Client: A pioneer and global leader in baby and child care brands and products, including diapers, wipes, and training pants.

Challenge: Manual quality assurance processes across 5 production lines were time-consuming, prone to inconsistencies, and limited in their ability to detect subtle defects, potentially impacting product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate visual inspection and enhance quality control across all production lines.

Results: Improved product consistency, reduced defect rates, enhanced brand reputation, and increased efficiency in quality assurance processes.

Client: A pioneer and global leader in baby and child care brands and products, including diapers, wipes, and training pants.

Challenge: Manual quality assurance processes across 5 production lines were time-consuming, prone to inconsistencies, and limited in their ability to detect subtle defects, potentially impacting product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate visual inspection and enhance quality control across all production lines.

Results: Improved product consistency, reduced defect rates, enhanced brand reputation, and increased efficiency in quality assurance processes.

Client: A pioneer and global leader in baby and child care brands and products, including diapers, wipes, and training pants.

Challenge: Manual quality assurance processes across 5 production lines were time-consuming, prone to inconsistencies, and limited in their ability to detect subtle defects, potentially impacting product quality and brand reputation.

Solution: InovarTech implemented VisionGuard, a custom AI-powered vision solution, to automate visual inspection and enhance quality control across all production lines.

Results: Improved product consistency, reduced defect rates, enhanced brand reputation, and increased efficiency in quality assurance processes.

Baby Care

Baby Care

Baby Care

Automated Inspection

Automated Inspection

Automated Inspection

Diapers, Manufacturing

Diapers, Manufacturing

Diapers, Manufacturing

AI Vision

AI Vision

AI Vision

Diapers

Diapers

Diapers

Production Line

Production Line

Production Line

The Challenge:

Maintaining High Standards in Baby Care Manufacturing

The Challenge:

Maintaining High Standards in Baby Care Manufacturing

The Challenge:

Maintaining High Standards in Baby Care Manufacturing

For a global leader in baby care products, ensuring consistent quality and safety is paramount. Our client faced challenges in maintaining these high standards across their diverse product lines and production facilities.

For a global leader in baby care products, ensuring consistent quality and safety is paramount. Our client faced challenges in maintaining these high standards across their diverse product lines and production facilities.

For a global leader in baby care products, ensuring consistent quality and safety is paramount. Our client faced challenges in maintaining these high standards across their diverse product lines and production facilities.

Manual Inspection: The existing quality assurance process involved manual inspection of a randomly selected product every 5 minutes from each of their 5 production lines. This process was labor-intensive and prone to human error.

Manual Inspection: The existing quality assurance process involved manual inspection of a randomly selected product every 5 minutes from each of their 5 production lines. This process was labor-intensive and prone to human error.

Manual Inspection: The existing quality assurance process involved manual inspection of a randomly selected product every 5 minutes from each of their 5 production lines. This process was labor-intensive and prone to human error.

Subtle Defects: Inspectors had to check for a wide range of subtle defects, including inconsistent absorbency, leakage, uneven tapes, skewed elastics, faulty seams, inconsistent leg cuff fit, issues with the non-woven fabric, and size inconsistencies.

Subtle Defects: Inspectors had to check for a wide range of subtle defects, including inconsistent absorbency, leakage, uneven tapes, skewed elastics, faulty seams, inconsistent leg cuff fit, issues with the non-woven fabric, and size inconsistencies.

Subtle Defects: Inspectors had to check for a wide range of subtle defects, including inconsistent absorbency, leakage, uneven tapes, skewed elastics, faulty seams, inconsistent leg cuff fit, issues with the non-woven fabric, and size inconsistencies.

Brand Risk: Any lapse in quality could negatively impact the brand's reputation and erode consumer trust.

Brand Risk: Any lapse in quality could negatively impact the brand's reputation and erode consumer trust.

Brand Risk: Any lapse in quality could negatively impact the brand's reputation and erode consumer trust.

Production Efficiency: Manual inspection created interruptions in the production flow and limited the ability to identify and address quality issues in real-time.

Production Efficiency: Manual inspection created interruptions in the production flow and limited the ability to identify and address quality issues in real-time.

Production Efficiency: Manual inspection created interruptions in the production flow and limited the ability to identify and address quality issues in real-time.

The Solution

The Solution

The Solution

VisionGuard – A Watchful Eye on Quality

VisionGuard – A Watchful Eye on Quality

VisionGuard – A Watchful Eye on Quality

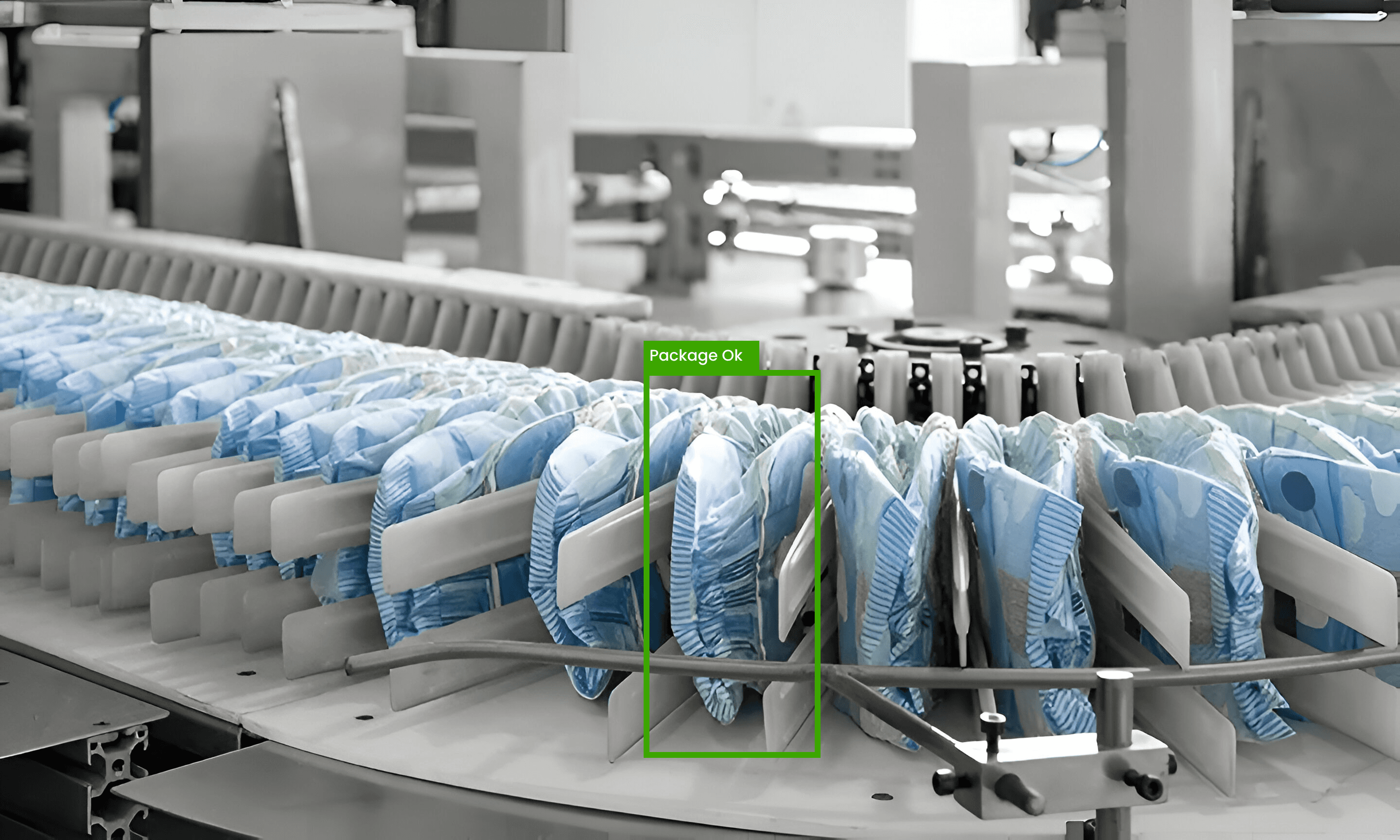

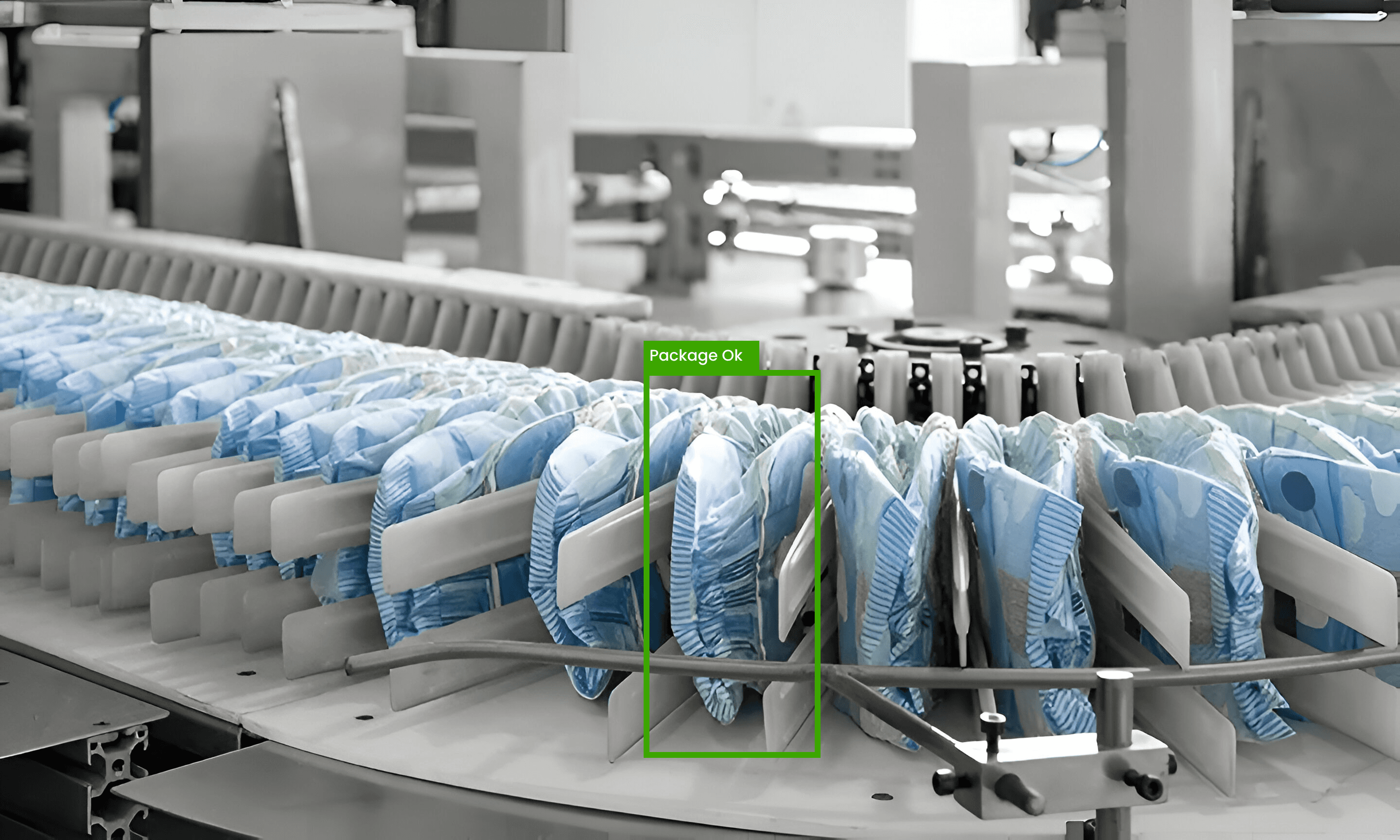

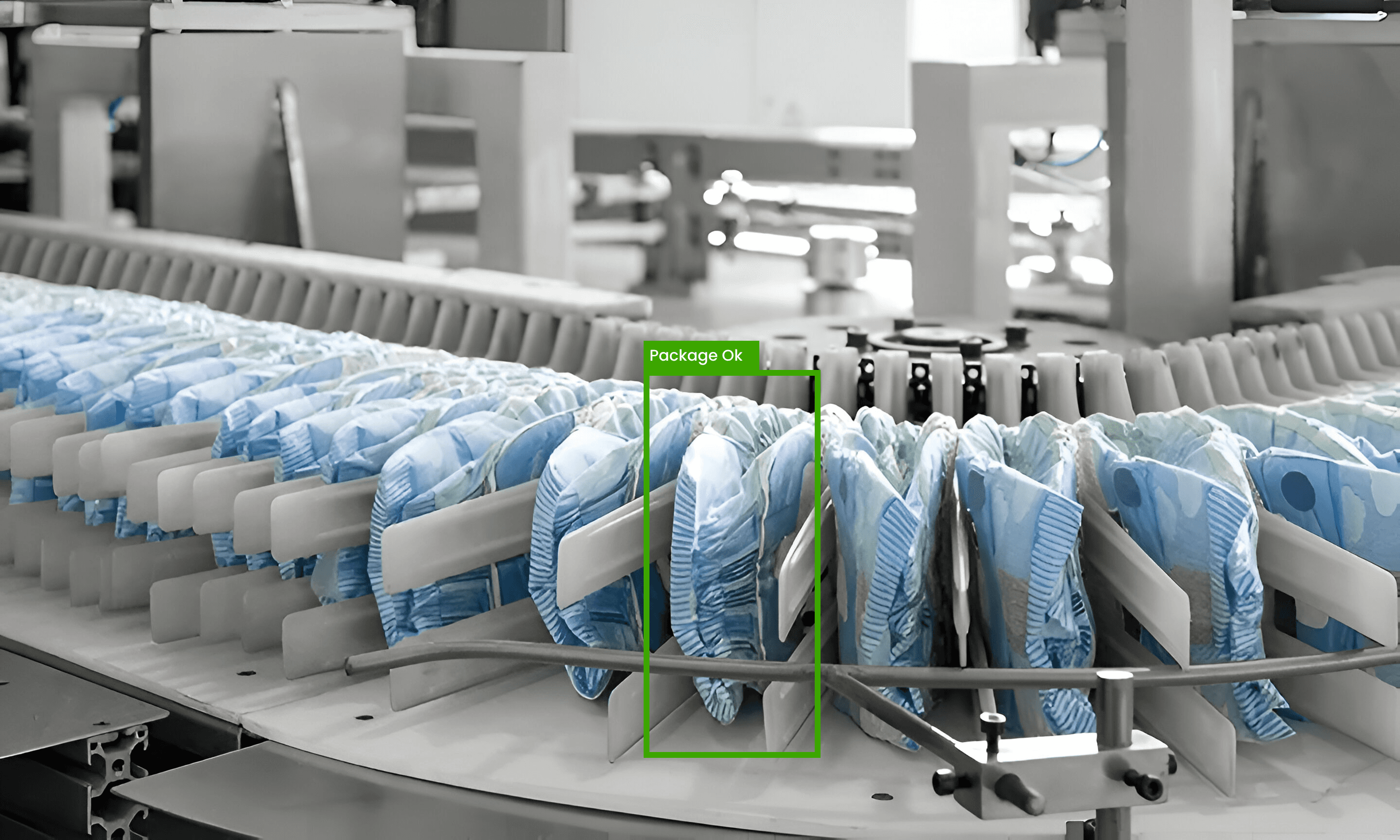

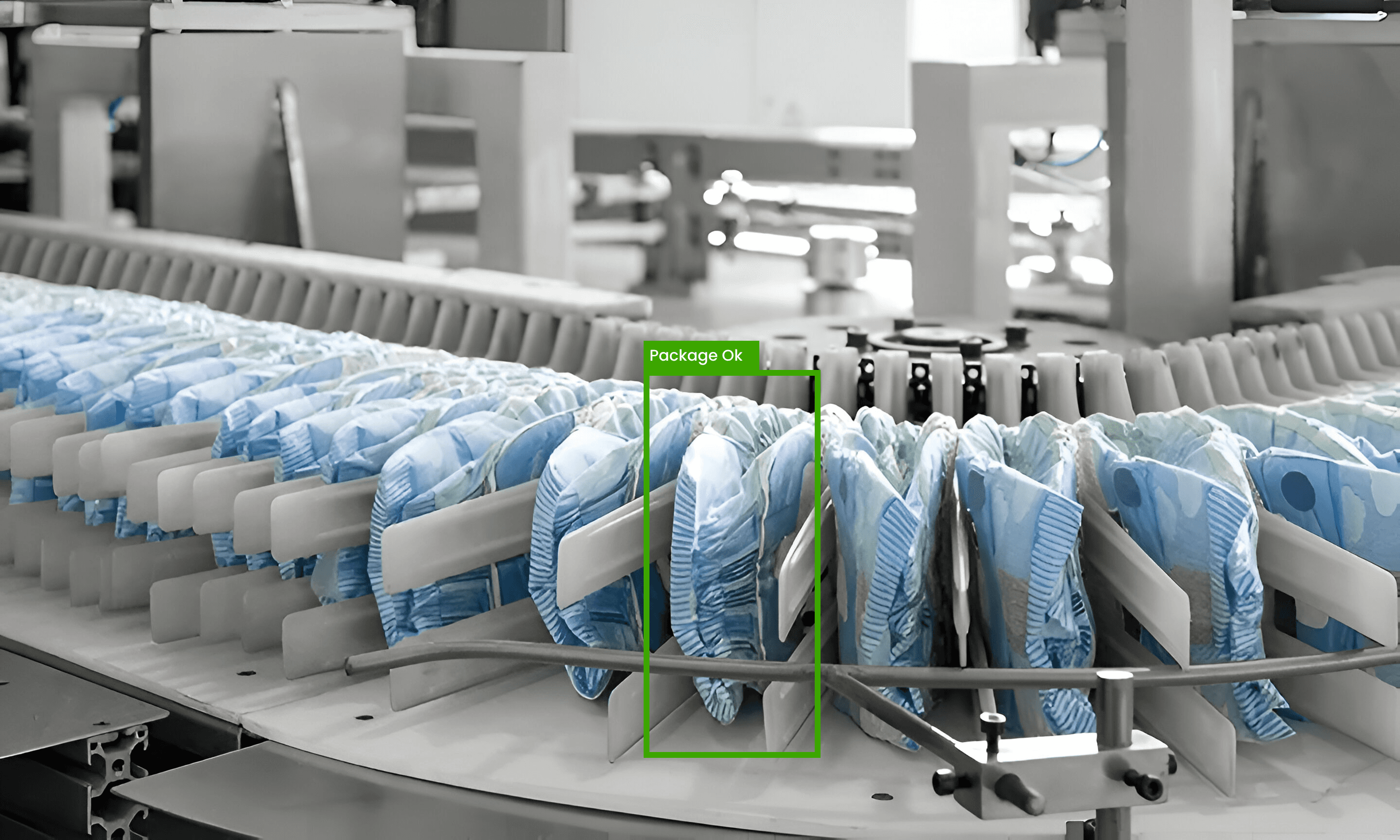

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the client's quality control process.

InovarTech implemented VisionGuard, a custom AI vision solution, to transform the client's quality control process.

Implementation Approach

Implementation Approach

Collaboration and Understanding: InovarTech worked closely with the client's production and quality teams to understand the specific requirements and challenges of each product line.

Collaboration and Understanding: InovarTech worked closely with the client's production and quality teams to understand the specific requirements and challenges of each product line.

Collaboration and Understanding: InovarTech worked closely with the client's production and quality teams to understand the specific requirements and challenges of each product line.

Tailored AI/ML Models: InovarTech developed custom AI/ML models trained on a vast dataset of product images to accurately detect a wide range of defects, including those related to absorbency, component placement, seams, fabric, adhesives, and dimensions.

Tailored AI/ML Models: InovarTech developed custom AI/ML models trained on a vast dataset of product images to accurately detect a wide range of defects, including those related to absorbency, component placement, seams, fabric, adhesives, and dimensions.

Tailored AI/ML Models: InovarTech developed custom AI/ML models trained on a vast dataset of product images to accurately detect a wide range of defects, including those related to absorbency, component placement, seams, fabric, adhesives, and dimensions.

Hardware Integration: High-resolution cameras and sensors were installed at key points on each production line to capture images of the products during the manufacturing process.

Hardware Integration: High-resolution cameras and sensors were installed at key points on each production line to capture images of the products during the manufacturing process.

Hardware Integration: High-resolution cameras and sensors were installed at key points on each production line to capture images of the products during the manufacturing process.

Real-time Monitoring and Reporting: VisionGuard provided a centralized dashboard for monitoring all 5 production lines in real-time, with automated alerts and email reports for any detected defects.

Real-time Monitoring and Reporting: VisionGuard provided a centralized dashboard for monitoring all 5 production lines in real-time, with automated alerts and email reports for any detected defects.

Real-time Monitoring and Reporting: VisionGuard provided a centralized dashboard for monitoring all 5 production lines in real-time, with automated alerts and email reports for any detected defects.

Key Capabilities

Key Capabilities

Comprehensive Defect Detection: VisionGuard accurately identified a wide range of defects, exceeding the capabilities of manual inspection.

Comprehensive Defect Detection: VisionGuard accurately identified a wide range of defects, exceeding the capabilities of manual inspection.

Comprehensive Defect Detection: VisionGuard accurately identified a wide range of defects, exceeding the capabilities of manual inspection.

Real-time Feedback: The system provided immediate feedback to production line operators, enabling them to address quality issues promptly and minimize waste.

Real-time Feedback: The system provided immediate feedback to production line operators, enabling them to address quality issues promptly and minimize waste.

Real-time Feedback: The system provided immediate feedback to production line operators, enabling them to address quality issues promptly and minimize waste.

Data-Driven Insights: VisionGuard generated detailed reports and analytics, providing valuable insights into quality trends and potential areas for improvement.

Data-Driven Insights: VisionGuard generated detailed reports and analytics, providing valuable insights into quality trends and potential areas for improvement.

Data-Driven Insights: VisionGuard generated detailed reports and analytics, providing valuable insights into quality trends and potential areas for improvement.

Enhanced Consistency: By automating the inspection process, VisionGuard ensured consistent quality control across all production lines and minimized variations in product quality.

Enhanced Consistency: By automating the inspection process, VisionGuard ensured consistent quality control across all production lines and minimized variations in product quality.

Enhanced Consistency: By automating the inspection process, VisionGuard ensured consistent quality control across all production lines and minimized variations in product quality.

The Results: Protecting Brand Reputation and Ensuring Product Excellence

The Results: Protecting Brand Reputation and Ensuring Product Excellence

The Results: Protecting Brand Reputation and Ensuring Product Excellence

The Results: Protecting Brand Reputation and Ensuring Product Excellence

The implementation of VisionGuard delivered significant benefits:

The implementation of VisionGuard delivered significant benefits:

The implementation of VisionGuard delivered significant benefits:

Improved Product Quality: The AI-powered system significantly reduced defect rates by 98%, ensuring that products met the highest quality standards.

Improved Product Quality: The AI-powered system significantly reduced defect rates by 98%, ensuring that products met the highest quality standards.

Improved Product Quality: The AI-powered system significantly reduced defect rates by 98%, ensuring that products met the highest quality standards.

Enhanced Brand Reputation: By consistently delivering high-quality products, VisionGuard helped protect the client's brand reputation and maintain consumer trust.

Enhanced Brand Reputation: By consistently delivering high-quality products, VisionGuard helped protect the client's brand reputation and maintain consumer trust.

Enhanced Brand Reputation: By consistently delivering high-quality products, VisionGuard helped protect the client's brand reputation and maintain consumer trust.

Increased Efficiency: Automated inspection streamlined the quality assurance process, improving production efficiency and reducing labor costs.

Increased Efficiency: Automated inspection streamlined the quality assurance process, improving production efficiency and reducing labor costs.

Increased Efficiency: Automated inspection streamlined the quality assurance process, improving production efficiency and reducing labor costs.

Data-Driven Decision Making: Real-time data and analytics provided valuable insights for continuous improvement and optimization of production processes.

Data-Driven Decision Making: Real-time data and analytics provided valuable insights for continuous improvement and optimization of production processes.

Data-Driven Decision Making: Real-time data and analytics provided valuable insights for continuous improvement and optimization of production processes.

“

“

InovarTechTech’s AI Vision Solution has been instrumental in enhancing our quality control processes. The system's ability to detect subtle defects and provide real-time feedback has allowed us to significantly improve product consistency and ensure that we are delivering the highest quality baby care products to our customers.

InovarTechTech’s AI Vision Solution has been instrumental in enhancing our quality control processes. The system's ability to detect subtle defects and provide real-time feedback has allowed us to significantly improve product consistency and ensure that we are delivering the highest quality baby care products to our customers.

"I set up a consultation and was blown away by how professional and helpful my advisor was. Highly recommend this service to everyone."

Emmeline Carson

Emmeline Carson

Emmeline Carson

Head of Production

Head of Production

Head of Production

The Future:

AI-Powered Quality Assurance for Consumer Confidence

The Future:

AI-Powered Quality Assurance for Consumer Confidence

The Future:

AI-Powered Quality Assurance for Consumer Confidence

This implementation showcases the power of AI vision to transform quality control in the consumer goods industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

This implementation showcases the power of AI vision to transform quality control in the consumer goods industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

This implementation showcases the power of AI vision to transform quality control in the consumer goods industry. By automating visual inspection, improving accuracy, and enhancing efficiency, AI enables organizations to:

Ensure consistent product quality and safety

Ensure consistent product quality and safety

Ensure consistent product quality and safety

Protect brand reputation and build consumer trust

Protect brand reputation and build consumer trust

Protect brand reputation and build consumer trust

Optimize production processes and reduce costs

Optimize production processes and reduce costs

Optimize production processes and reduce costs

Drive innovation and adopt advanced manufacturing techniques

Drive innovation and adopt advanced manufacturing techniques

Drive innovation and adopt advanced manufacturing techniques

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering consumer goods companies to achieve new levels of quality and efficiency in their manufacturing processes.

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering consumer goods companies to achieve new levels of quality and efficiency in their manufacturing processes.

InovarTech, with its VisionGuard solution, is at the forefront of this transformation, empowering consumer goods companies to achieve new levels of quality and efficiency in their manufacturing processes.

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

InovarTech's AI-Powered Vision System Automates Defect Detection, Reduces Customer Rejections by 95%, and Optimizes Production for a Top 5 Plastics Manufacturer in India

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Global baby and adult care Multi-national achieves Product Excellence with AI-Powered Quality Control

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

More Case Studies

Leading PVC Manufacturer Eliminates Cracks and Boosts Quality with VisionGuard.AI

Omni-Channel Fashion Retailer achieves 30% Reduction in Support Tickets and Boosts Customer Loyalty with Agentic AI

Leading Cooking Oil Manufacturer in Saudi Arabia Enhances Food Safety with AI-Powered Visual Inspection

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved