Smart Factories Made Smarter with AI Vision

Smart Factories Made Smarter with AI Vision

Smart Factories Made Smarter with AI Vision

Smart Factories Made Smarter with AI Vision

Smart Factories Made Smarter with AI Vision

Smart Factories Made Smarter with AI Vision

Smart Factories Made Smarter with AI Vision

By Apratim Ghosh

By Apratim Ghosh

By Apratim Ghosh

Dec 10, 2024

Dec 10, 2024

Dec 10, 2024

Vision AI

Vision AI

AI solutions

AI solutions

Vision AI solution

Vision AI solution

White paper

White paper

AI Based Gross to Net (G2N) Solution

AI Based Gross to Net (G2N) Solution

Valuable Asset For Agri Science Company

Valuable Asset For Agri Science Company

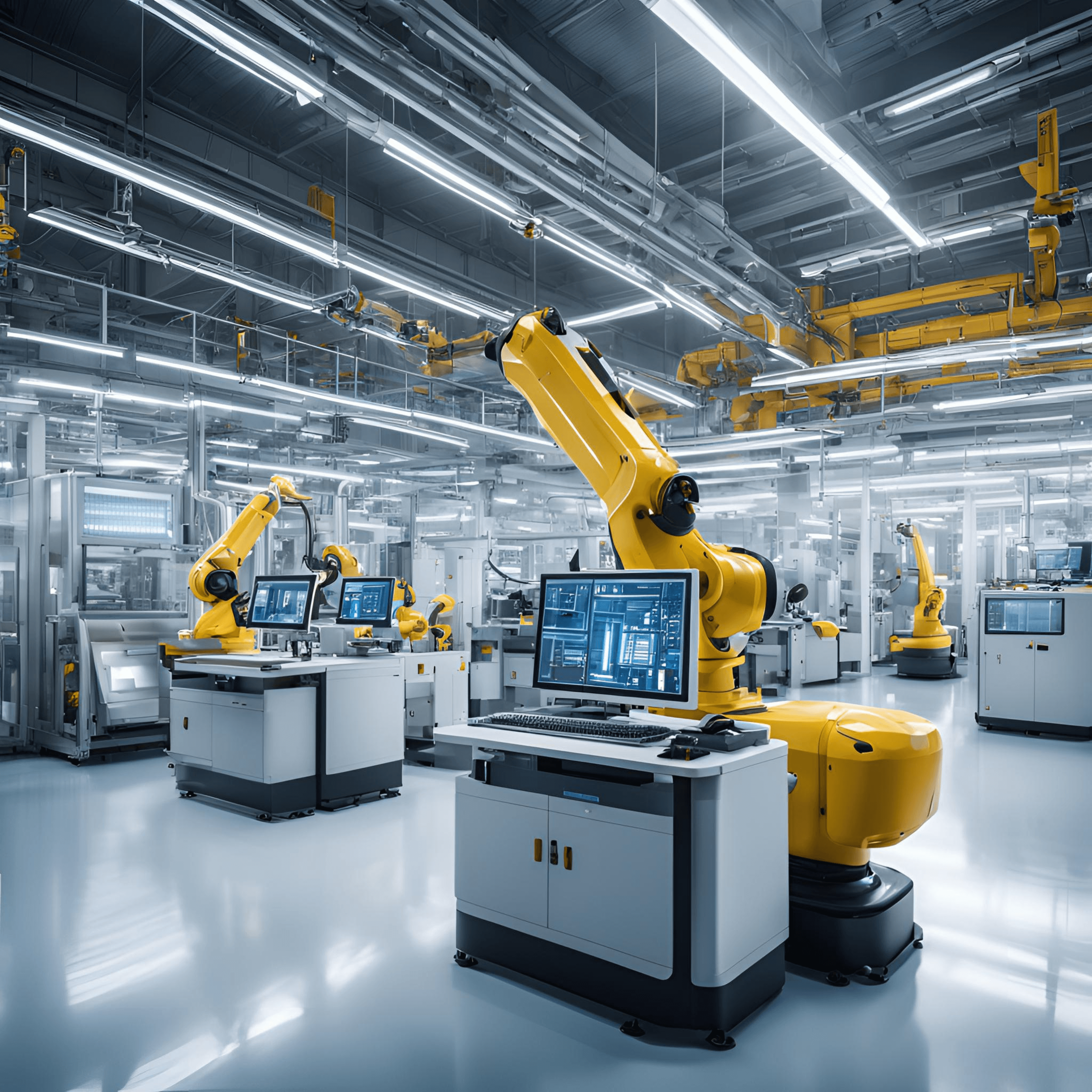

There is a rising demand from manufacturers globally to transition their production facilities into smart factories. In fact, studies estimate the global smart factory market size will reach a staggering USD 321.98 billion by 2032. While smart factories aren’t a new thing, key players in the segment are looking at ways to optimize their smart factories for better ROI. Vision AI platforms like VisionGuard AI can be a key component in enabling such success. But before we go into the depth of what it does, it is important to know about why smart factories need more strategic technologies for guaranteed success.

From automobiles to smartphones, manufacturers in multiple business domains are beginning to realize the benefits of a smarter and more connected production facility. As more factory assets get automated and connected to the Internet, decision-makers have access to more data from their operations. This allows them to optimally run their business with the right focus on maintenance, upgrades, production timelines, procurement, and much more.

A Deloitte survey pointed out that smart factories have provided gains of close to 12% in critical areas of manufacturing such as factory utilization, labor productivity, and output volume!

Smart factories play a critical role in helping manufacturers improve profitability while ensuring better business value for consumers through timely fulfillment of demand and superior quality assurance. The pandemic years also highlighted the need for automated factories as it helped minimize the physical interaction of human workers nearby inside factory floors.

As smart factories continue to make inroads in the manufacturing sector, there is also a critical need to ensure that they have the right technologies in place that guarantee quality of production and faster value creation.

The Need for Strategic Technologies in Smart Factories

With smart factories, decision-makers place a lot of trust in machines to deliver on committed supplies. While this is a huge advantage from a productivity perspective, there is a critical need for quality assurance. The tools, technology, and processes used in smart machinery should be reliable, resilient, and capable of enabling autonomous operations of the entire factory ecosystem. Ultimately it will help in increasing production capacity with lower risks and higher efficiency.

They should be data-driven, capture performance metrics continuously, stay always connected to central management consoles or dashboards, embrace intelligent decision-making through a range of analytical support systems, and much more. Quality slippage should always be avoided.

Let us explain with the example of an automated conveyor belt supplying components to different units within a smart factory. It will run on an automated schedule. Any quality issues will disrupt their schedules, and all downstream production activities will witness an escalating problem of delays and disruptions because of this. Additionally, quality issues can lead to expensive recalls of models which can hurt both financially as well as tarnish the brand’s reputation. In 2023, the US automobile giant Ford recalled almost 6 million cars due to an axle defect. Such a scenario can be a major blow for businesses like automobiles where manufacturers must strive to fulfill customer bookings in the shortest timeframe to optimize profits.

AI Vision as the Strategic Technology Advantage for Smart Factories

One of the best technologies that smart factories can embrace to ensure long-term success in their growth initiatives is AI Vision. Powered by AI, it brings the power of visual analytics to machines across the factory floor. It equips smart factories with a pair of smart eyes that allow them to analyze and discover hidden insights from within operations. This early detection will help in preparing remediation measures faster and ensure that defective products do not make it into the market from the production line.

Top Focus Areas for AI Vision in Smart Factories

We have seen the need for smart factories to have a clear and transparent understanding of their entire ecosystem to ensure better performance and lower risks. With AI Vision technology, this can be easily realized.

Let us explore a few areas where AI Vision can bring significant changes within a smart factory:

Quality Assurance

In manufacturing, the importance of quality control is quite high. With better quality, the brand cannot just save on maintenance costs for products, but also ensure a good reputation in the market. With AI Vision, it becomes easier to embed quality as an integral function in the factory floor itself. A Vision AI solution can easily check for product quality by checking its dimensions, surface texture, etc., and compare it with a standard model of expected outcomes. Any deviations observed can be used to reject the specific item and ensure it doesn’t get released to the market.

Faster Automation for Both Hardware and Software

Smart factories often involve plenty of moving components like robots moving packaged products or components across different production lines. Vision AI solutions can help ensure that such movements can occur at a rapid pace without any danger of collision or disruptions. Additionally, the efficiency of pickup hardware within the factory floor can be enhanced with AI Vision. Only the right labeled components or packages will be picked up and transferred after inspection. This can also aid in automated inventory management.

Enhance Worker Safety

AI Vision can help in monitoring worker conditions throughout the factory floor. Integrated cameras can help managers assess fatigue levels and the presence of safety hazards on work floors and aid in helping workers perform duties securely. For example, a Vision AI solution can restrict access to a worker who is not in proper safety gear. This would prevent him or her from being exposed to a hazardous environment.

AI Vision is a huge step for manufacturers toward achieving seamless ROI from their smart factories. What they need is the right solution with expert guidance on how to integrate it smoothly with the rest of the smart factory infrastructure.

This is where an expert partner like Inovar Tech can be the game changer. Get in touch with us to learn more about our state-of-the-art Vision AI platform VisionGuard AI and how it can help your smart factories beat the competition.

There is a rising demand from manufacturers globally to transition their production facilities into smart factories. In fact, studies estimate the global smart factory market size will reach a staggering USD 321.98 billion by 2032. While smart factories aren’t a new thing, key players in the segment are looking at ways to optimize their smart factories for better ROI. Vision AI platforms like VisionGuard AI can be a key component in enabling such success. But before we go into the depth of what it does, it is important to know about why smart factories need more strategic technologies for guaranteed success.

From automobiles to smartphones, manufacturers in multiple business domains are beginning to realize the benefits of a smarter and more connected production facility. As more factory assets get automated and connected to the Internet, decision-makers have access to more data from their operations. This allows them to optimally run their business with the right focus on maintenance, upgrades, production timelines, procurement, and much more.

A Deloitte survey pointed out that smart factories have provided gains of close to 12% in critical areas of manufacturing such as factory utilization, labor productivity, and output volume!

Smart factories play a critical role in helping manufacturers improve profitability while ensuring better business value for consumers through timely fulfillment of demand and superior quality assurance. The pandemic years also highlighted the need for automated factories as it helped minimize the physical interaction of human workers nearby inside factory floors.

As smart factories continue to make inroads in the manufacturing sector, there is also a critical need to ensure that they have the right technologies in place that guarantee quality of production and faster value creation.

The Need for Strategic Technologies in Smart Factories

With smart factories, decision-makers place a lot of trust in machines to deliver on committed supplies. While this is a huge advantage from a productivity perspective, there is a critical need for quality assurance. The tools, technology, and processes used in smart machinery should be reliable, resilient, and capable of enabling autonomous operations of the entire factory ecosystem. Ultimately it will help in increasing production capacity with lower risks and higher efficiency.

They should be data-driven, capture performance metrics continuously, stay always connected to central management consoles or dashboards, embrace intelligent decision-making through a range of analytical support systems, and much more. Quality slippage should always be avoided.

Let us explain with the example of an automated conveyor belt supplying components to different units within a smart factory. It will run on an automated schedule. Any quality issues will disrupt their schedules, and all downstream production activities will witness an escalating problem of delays and disruptions because of this. Additionally, quality issues can lead to expensive recalls of models which can hurt both financially as well as tarnish the brand’s reputation. In 2023, the US automobile giant Ford recalled almost 6 million cars due to an axle defect. Such a scenario can be a major blow for businesses like automobiles where manufacturers must strive to fulfill customer bookings in the shortest timeframe to optimize profits.

AI Vision as the Strategic Technology Advantage for Smart Factories

One of the best technologies that smart factories can embrace to ensure long-term success in their growth initiatives is AI Vision. Powered by AI, it brings the power of visual analytics to machines across the factory floor. It equips smart factories with a pair of smart eyes that allow them to analyze and discover hidden insights from within operations. This early detection will help in preparing remediation measures faster and ensure that defective products do not make it into the market from the production line.

Top Focus Areas for AI Vision in Smart Factories

We have seen the need for smart factories to have a clear and transparent understanding of their entire ecosystem to ensure better performance and lower risks. With AI Vision technology, this can be easily realized.

Let us explore a few areas where AI Vision can bring significant changes within a smart factory:

Quality Assurance

In manufacturing, the importance of quality control is quite high. With better quality, the brand cannot just save on maintenance costs for products, but also ensure a good reputation in the market. With AI Vision, it becomes easier to embed quality as an integral function in the factory floor itself. A Vision AI solution can easily check for product quality by checking its dimensions, surface texture, etc., and compare it with a standard model of expected outcomes. Any deviations observed can be used to reject the specific item and ensure it doesn’t get released to the market.

Faster Automation for Both Hardware and Software

Smart factories often involve plenty of moving components like robots moving packaged products or components across different production lines. Vision AI solutions can help ensure that such movements can occur at a rapid pace without any danger of collision or disruptions. Additionally, the efficiency of pickup hardware within the factory floor can be enhanced with AI Vision. Only the right labeled components or packages will be picked up and transferred after inspection. This can also aid in automated inventory management.

Enhance Worker Safety

AI Vision can help in monitoring worker conditions throughout the factory floor. Integrated cameras can help managers assess fatigue levels and the presence of safety hazards on work floors and aid in helping workers perform duties securely. For example, a Vision AI solution can restrict access to a worker who is not in proper safety gear. This would prevent him or her from being exposed to a hazardous environment.

AI Vision is a huge step for manufacturers toward achieving seamless ROI from their smart factories. What they need is the right solution with expert guidance on how to integrate it smoothly with the rest of the smart factory infrastructure.

This is where an expert partner like Inovar Tech can be the game changer. Get in touch with us to learn more about our state-of-the-art Vision AI platform VisionGuard AI and how it can help your smart factories beat the competition.

Get in Touch

Get in Touch

Related Blogs

Related Blogs

Related Blogs

Related Blogs

Join our Newsletter 👇,

Join our Newsletter 👇,

Join our Newsletter 👇,

Join our Newsletter 👇,

Want the latest technology updates & business trends in your inbox? Subscribe to our newsletter and experience reading really interesting and informative.

Want the latest technology updates & business trends in your inbox? Subscribe to our newsletter and experience reading really interesting and informative.

Your email address

Sign me up

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved