Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

Beyond Counting: How Automation and Vision AI Enhances Packaging Efficiency

By Apratim Ghosh

By Apratim Ghosh

By Apratim Ghosh

Dec 11, 2024

Dec 11, 2024

Dec 11, 2024

Vision AI

Vision AI

AI Vision

AI Vision

Vision AI solution

Vision AI solution

Listen to this blog :

0:00/1:34

White paper

White paper

AI Based Gross to Net (G2N) Solution

AI Based Gross to Net (G2N) Solution

Valuable Asset For Agri Science Company

Valuable Asset For Agri Science Company

Product counting is an integral part of the packaging process. It is more effective than weighing, especially for small products like a coin or plastic mold, where the weight deviation could be 1-2% off.

For example, let’s assume a factory is packing a bag of 100 Q-tips. The worker weighs all the Q-tips till they reach the specific weight. However, there is a chance that all the packages don’t have a perfect number of Q-tips. Some packages could have less than 100 Q-tips, and some could have more. The inaccuracy in the quantity of products could leave the customer dissatisfied and ruin the manufacturer’s reputation.

This makes counting a better option than weighing. But counting also has its shortcomings, especially when done manually.

Let’s go back to the Q-tip example. Let’s assume the worker manually counts the Q-tips instead of weighing them. He could be staring at a pile of Q-tips strewn all over the factory floor. The mundane task of counting Q-tips could lead to problems like distraction among workers due to the fatigue of counting manually, errors in the packaging process, and disgruntled customers.

It becomes even more challenging when manufacturers have to meet a demanding packaging schedule or if a company is packing life-saving drugs where a minor error could lead to serious repercussions.

That’s where automation and Vision AI come to the rescue.

How Can Automation and Vision AI Improve Product Counting?

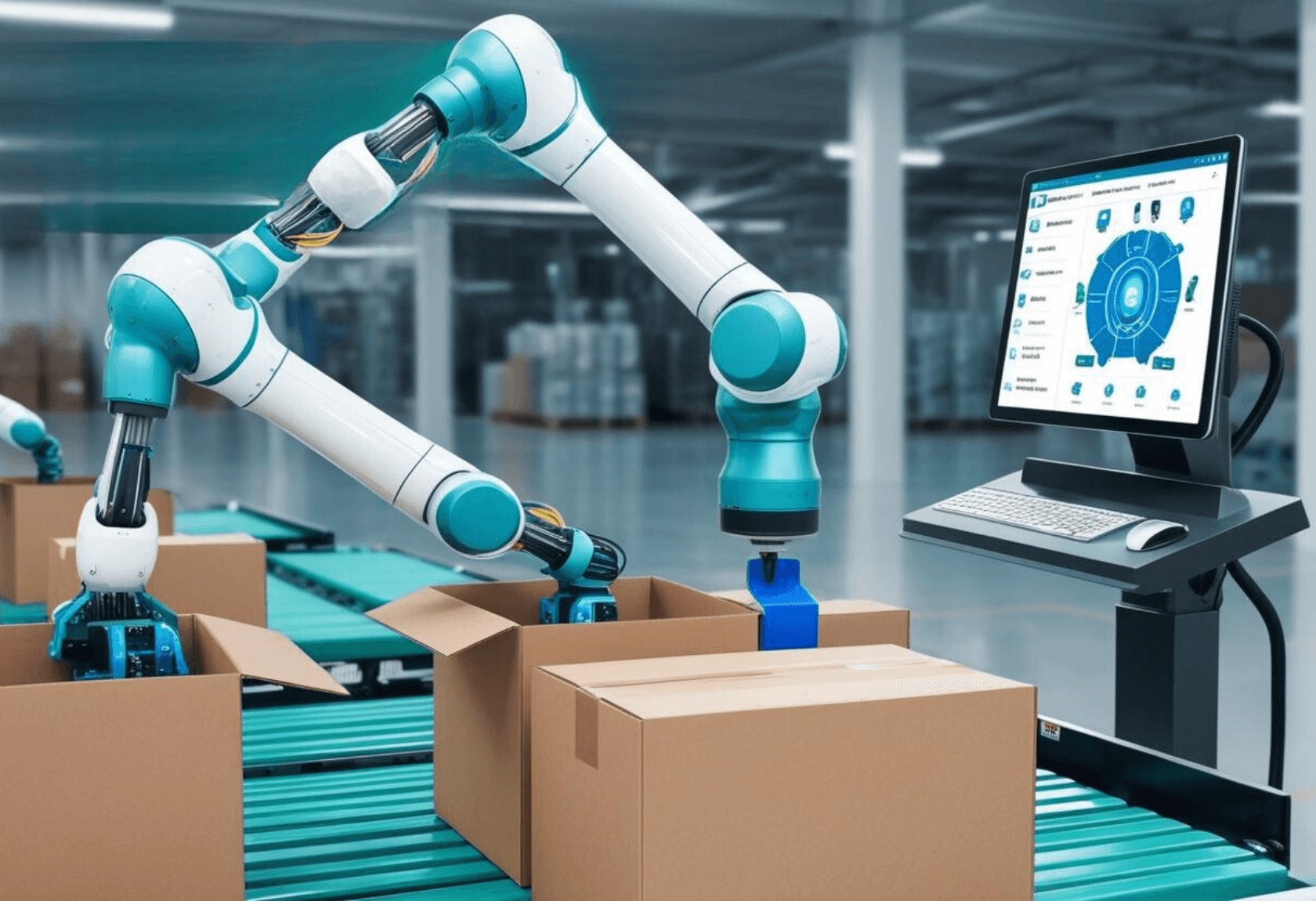

Vision AI uses a combination of cameras, computer vision systems, and image processing algorithms to automate product counting. For example, the camera captures images of the products on the conveyor belt, and the Vision AI solution counts each item and detects errors in real-time. It allows the workers to rectify the errors during production and minimize errors common in manual counting. With AI Vision, manufacturers can accelerate the counting process, improve accuracy, and reduce waste. It is especially beneficial while producing products on a large scale.

How Automation and Vision AI Can Enhance Packaging Efficiency?

Besides product counting, Vision AI and automation are also helpful in streamlining other aspects of the packaging process.

It can help manufacturers:

Reduce packaging waste by maintaining packaging integrity

Packaging integrity is crucial to maintaining the product’s quality and customer trust. For example, a broken seal could reduce a product's shelf life and result in misunderstanding among customers. Vision AI can mitigate this problem by inspecting the seals using high-resolution cameras and segmenting them as sealed or unsealed products. This ensures that only fully sealed products reach the customers and minimizes packaging waste and associated expenses in recalling them. It is also helpful in choosing the optimal packaging material and type for products and improving sustainability. Take Amazon, for instance. They follow the Package Decision Engine process in which the products arriving at the Amazon fulfillment center go through the Vision AI tunnel to determine their dimensions, spot defects, and see any exposed glasses, bags, or boxes around them. Based on this information, Amazon chooses the suitable packaging for the product. This has helped Amazon avoid two million tons of packaging material worldwide since 2015.

Detect labeling issues

Vision AI can detect the most minute issues that are not easily visible to the naked eye. It uses advanced algorithms to precisely analyze images and identify subtle inconsistencies, such as misaligned labels, color discrepancies, or text alignment. It is also helpful in identifying counterfeit products. For example, it can analyze finer details like microprinting, holograms, and minor variations in packaging designs. This helps manufacturers prevent fake products from reaching customers and safeguard the brand and customers from the risks of counterfeiting. It is especially critical in highly regulated industries like pharmaceuticals, where counterfeiting is common.

Ensure continuous production

Vision AI, with the help of machine learning, constantly learns from the products it inspects. This makes detecting defects more efficient and accurate, enabling machines to adapt to new packaging designs. It also helps with preventive maintenance, which reduces downtime and ensures continuous production. In an ever-evolving market where product life cycles are short, and customer preferences change constantly, continuous production and adaptability help manufacturers meet the demands and stay ahead of the competition.

Optimize packaging design

A good packaging design is integral to a brand’s reputation. Vision AI can detect defects in the packaging's appearance, shape, and size and continuously learn from the defects to improve future designs.

Conclusion

Product counting is essential to maintaining packaging accuracy and winning customers' trust. However, the process will be riddled with errors and inefficiency if done manually. That’s why Vision AI is necessary. It automates the counting process and improves the accuracy and efficiency of the packaging process. It is a perfect solution for companies that produce small items or large-scale production. Besides counting, manufacturers can use Vision AI to optimize packaging designs, detect label issues, and ensure continuous production by reducing downtime.

At InovarTech, we understand the challenges of unreliable quality checks and inspections. To combat these challenges, we developed Vision Guard AI - an AI-driven inspection solution that streamlines the quality control process. Vision Guard AI fits smoothly into the existing workflows and uses advanced machine learning models and machine vision algorithms to conduct real-time inspections and pinpoint subtle defects. Our product goes beyond counting and increases productivity and efficiency in the packaging process.

Product counting is an integral part of the packaging process. It is more effective than weighing, especially for small products like a coin or plastic mold, where the weight deviation could be 1-2% off.

For example, let’s assume a factory is packing a bag of 100 Q-tips. The worker weighs all the Q-tips till they reach the specific weight. However, there is a chance that all the packages don’t have a perfect number of Q-tips. Some packages could have less than 100 Q-tips, and some could have more. The inaccuracy in the quantity of products could leave the customer dissatisfied and ruin the manufacturer’s reputation.

This makes counting a better option than weighing. But counting also has its shortcomings, especially when done manually.

Let’s go back to the Q-tip example. Let’s assume the worker manually counts the Q-tips instead of weighing them. He could be staring at a pile of Q-tips strewn all over the factory floor. The mundane task of counting Q-tips could lead to problems like distraction among workers due to the fatigue of counting manually, errors in the packaging process, and disgruntled customers.

It becomes even more challenging when manufacturers have to meet a demanding packaging schedule or if a company is packing life-saving drugs where a minor error could lead to serious repercussions.

That’s where automation and Vision AI come to the rescue.

How Can Automation and Vision AI Improve Product Counting?

Vision AI uses a combination of cameras, computer vision systems, and image processing algorithms to automate product counting. For example, the camera captures images of the products on the conveyor belt, and the Vision AI solution counts each item and detects errors in real-time. It allows the workers to rectify the errors during production and minimize errors common in manual counting. With AI Vision, manufacturers can accelerate the counting process, improve accuracy, and reduce waste. It is especially beneficial while producing products on a large scale.

How Automation and Vision AI Can Enhance Packaging Efficiency?

Besides product counting, Vision AI and automation are also helpful in streamlining other aspects of the packaging process.

It can help manufacturers:

Reduce packaging waste by maintaining packaging integrity

Packaging integrity is crucial to maintaining the product’s quality and customer trust. For example, a broken seal could reduce a product's shelf life and result in misunderstanding among customers. Vision AI can mitigate this problem by inspecting the seals using high-resolution cameras and segmenting them as sealed or unsealed products. This ensures that only fully sealed products reach the customers and minimizes packaging waste and associated expenses in recalling them. It is also helpful in choosing the optimal packaging material and type for products and improving sustainability. Take Amazon, for instance. They follow the Package Decision Engine process in which the products arriving at the Amazon fulfillment center go through the Vision AI tunnel to determine their dimensions, spot defects, and see any exposed glasses, bags, or boxes around them. Based on this information, Amazon chooses the suitable packaging for the product. This has helped Amazon avoid two million tons of packaging material worldwide since 2015.

Detect labeling issues

Vision AI can detect the most minute issues that are not easily visible to the naked eye. It uses advanced algorithms to precisely analyze images and identify subtle inconsistencies, such as misaligned labels, color discrepancies, or text alignment. It is also helpful in identifying counterfeit products. For example, it can analyze finer details like microprinting, holograms, and minor variations in packaging designs. This helps manufacturers prevent fake products from reaching customers and safeguard the brand and customers from the risks of counterfeiting. It is especially critical in highly regulated industries like pharmaceuticals, where counterfeiting is common.

Ensure continuous production

Vision AI, with the help of machine learning, constantly learns from the products it inspects. This makes detecting defects more efficient and accurate, enabling machines to adapt to new packaging designs. It also helps with preventive maintenance, which reduces downtime and ensures continuous production. In an ever-evolving market where product life cycles are short, and customer preferences change constantly, continuous production and adaptability help manufacturers meet the demands and stay ahead of the competition.

Optimize packaging design

A good packaging design is integral to a brand’s reputation. Vision AI can detect defects in the packaging's appearance, shape, and size and continuously learn from the defects to improve future designs.

Conclusion

Product counting is essential to maintaining packaging accuracy and winning customers' trust. However, the process will be riddled with errors and inefficiency if done manually. That’s why Vision AI is necessary. It automates the counting process and improves the accuracy and efficiency of the packaging process. It is a perfect solution for companies that produce small items or large-scale production. Besides counting, manufacturers can use Vision AI to optimize packaging designs, detect label issues, and ensure continuous production by reducing downtime.

At InovarTech, we understand the challenges of unreliable quality checks and inspections. To combat these challenges, we developed Vision Guard AI - an AI-driven inspection solution that streamlines the quality control process. Vision Guard AI fits smoothly into the existing workflows and uses advanced machine learning models and machine vision algorithms to conduct real-time inspections and pinpoint subtle defects. Our product goes beyond counting and increases productivity and efficiency in the packaging process.

Get in Touch

Get in Touch

Related Blogs

Related Blogs

Related Blogs

Related Blogs

Join our Newsletter 👇,

Join our Newsletter 👇,

Join our Newsletter 👇,

Join our Newsletter 👇,

Want the latest technology updates & business trends in your inbox? Subscribe to our newsletter and experience reading really interesting and informative.

Want the latest technology updates & business trends in your inbox? Subscribe to our newsletter and experience reading really interesting and informative.

Your email address

Sign me up

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved