AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

AI-Powered Quality Control: Ensuring Patient Safety and Product Integrity in Pharma

By Apratim Ghosh

By Apratim Ghosh

By Apratim Ghosh

Dec 11, 2024

Dec 11, 2024

Dec 11, 2024

AI-Powered

AI-Powered

copilot services

copilot services

Copilot services partner

Copilot services partner

White paper

White paper

AI Based Gross to Net (G2N) Solution

AI Based Gross to Net (G2N) Solution

Valuable Asset For Agri Science Company

Valuable Asset For Agri Science Company

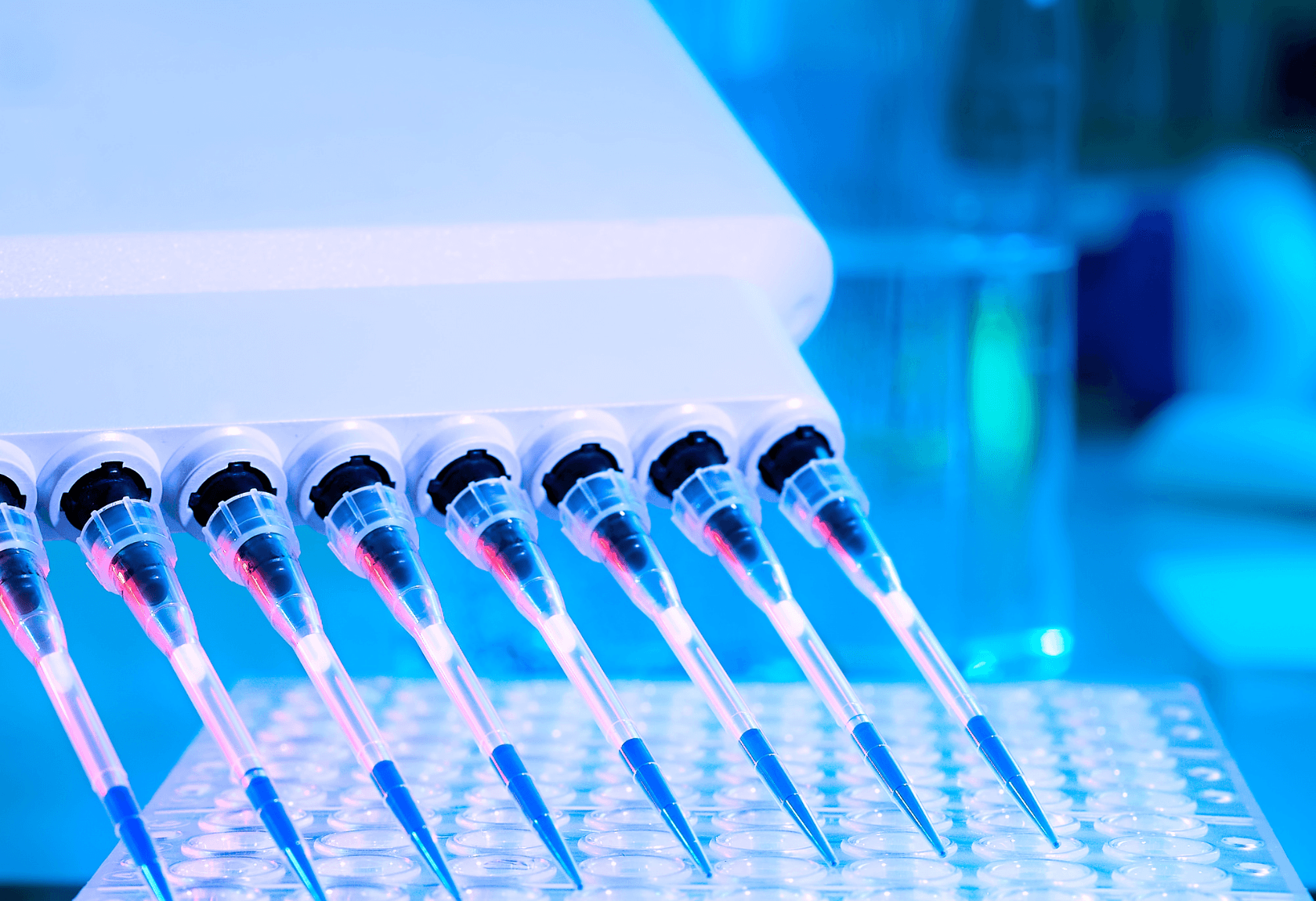

Quality and product integrity are paramount in the pharmaceutical industry.

Even a minute lapse could lead to delays in product releases and drug shortages. If a lapse slips through the cracks and reaches patients, pharmaceutical companies will have to track and recall the drug, trace the errors, and do a root cause analysis to take immediate remedial action.

Besides being a long-drawn process, quality oversight could attract heavy fines for the company and damage its reputation.

The obvious solution is to improve the quality of products. However, it’s not simple.

While regulations like the Drugs Administration’s (FDA) Good Manufacturing Practices (GMP) and the World Health Organization’s (WHO) basic frameworks call for strict compliance, pharmaceutical companies are having trouble complying with them.

There could be various reasons for that:

Manufacturers have no control over raw materials or suppliers and no process for accepting or rejecting the materials

Human errors like skipping or repeating a step, lack of skills to perform tasks, non-adherence due to complex instructions, and more

Old or faulty equipment that could affect a drug’s quality

Other inconsistencies like discoloration of capsule surfaces and injection solution, cracks or splits in capsules, variations in the volume of pills and liquids in an injection vial, and sediments and particulate matter in injections, eyedrops, and syrups

Inaccurate pill counting due to incorrect scooping technique or human oversight, which could lead to less than prescribed medicines being packed in the bottle

Labeling issues such as smudges due to dirty printer rollers, printing and spelling errors, and incomplete or inaccurate information

The list is endless, and it’s clear that manual intervention is not enough for pharma companies to perform quality checks and ensure patient safety.

Automating quality control and using AI-powered computer vision is the only way to mitigate these issues.

How AI-Powered Computer Vision Can Help Pharma Companies Maintain Product Integrity and Patient Safety

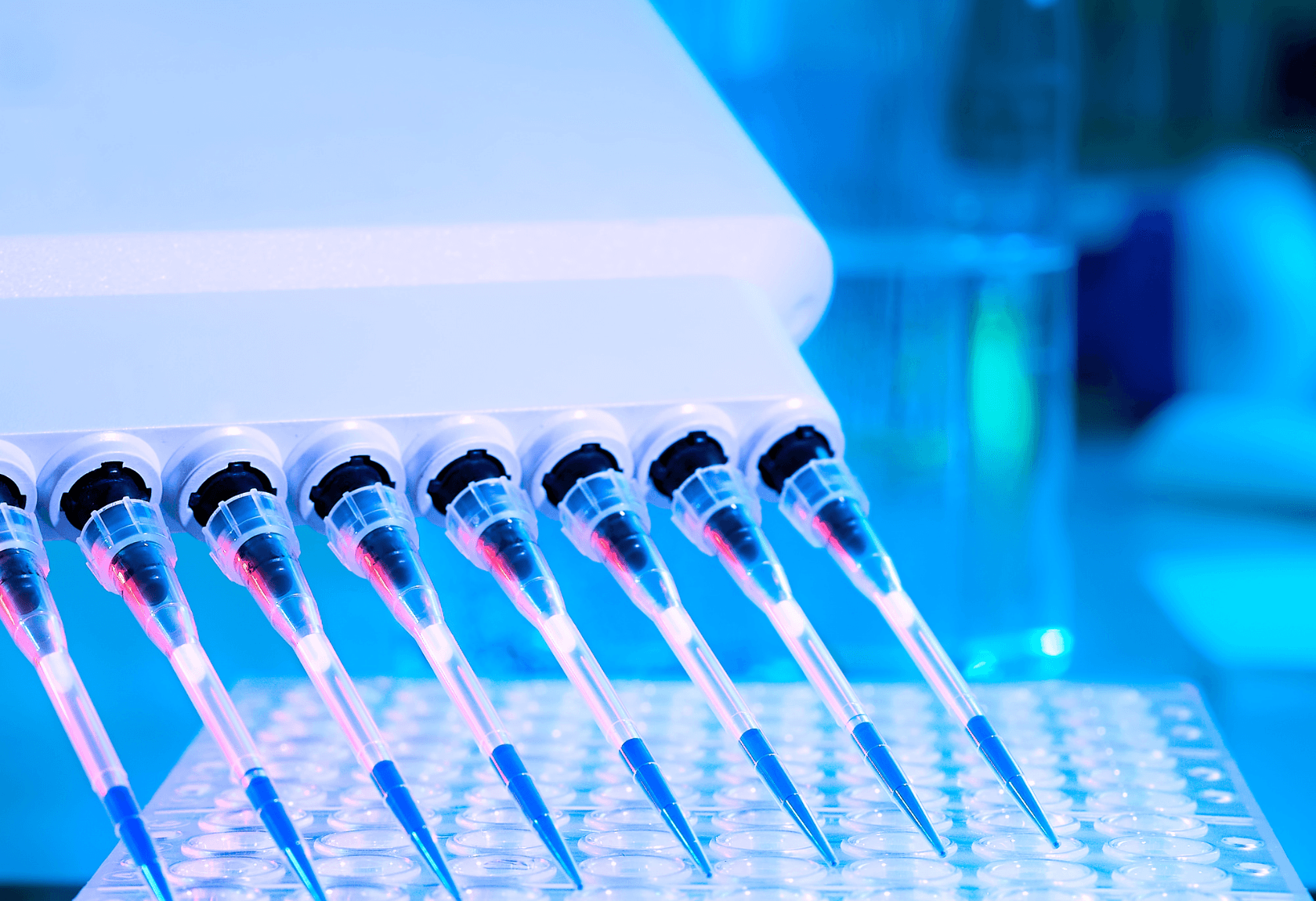

In 2021, the European Journal of Pharmaceutical Sciences published a study on computer vision applications in pharmaceutical technology. The study’s objective was to understand how computer vision, digital cameras, and image analysis software could help pharmaceutical companies improve the efficiency and reliability of pharmaceutical manufacturing.

The study involved using digital cameras to capture images of pharmaceutical processes and materials, processing the images for analysis, segmenting them, and leveraging computer vision to monitor pharmaceutical processes like crystallization, granulation, and tablet coating.

The experiment demonstrated that computer vision can help pharma companies analyze the size, shape, color, and texture of different pharmaceutical materials and enhance the quality of medicines.

Let’s look at more use cases to understand how computer vision can play a role in product integrity and patient safety.

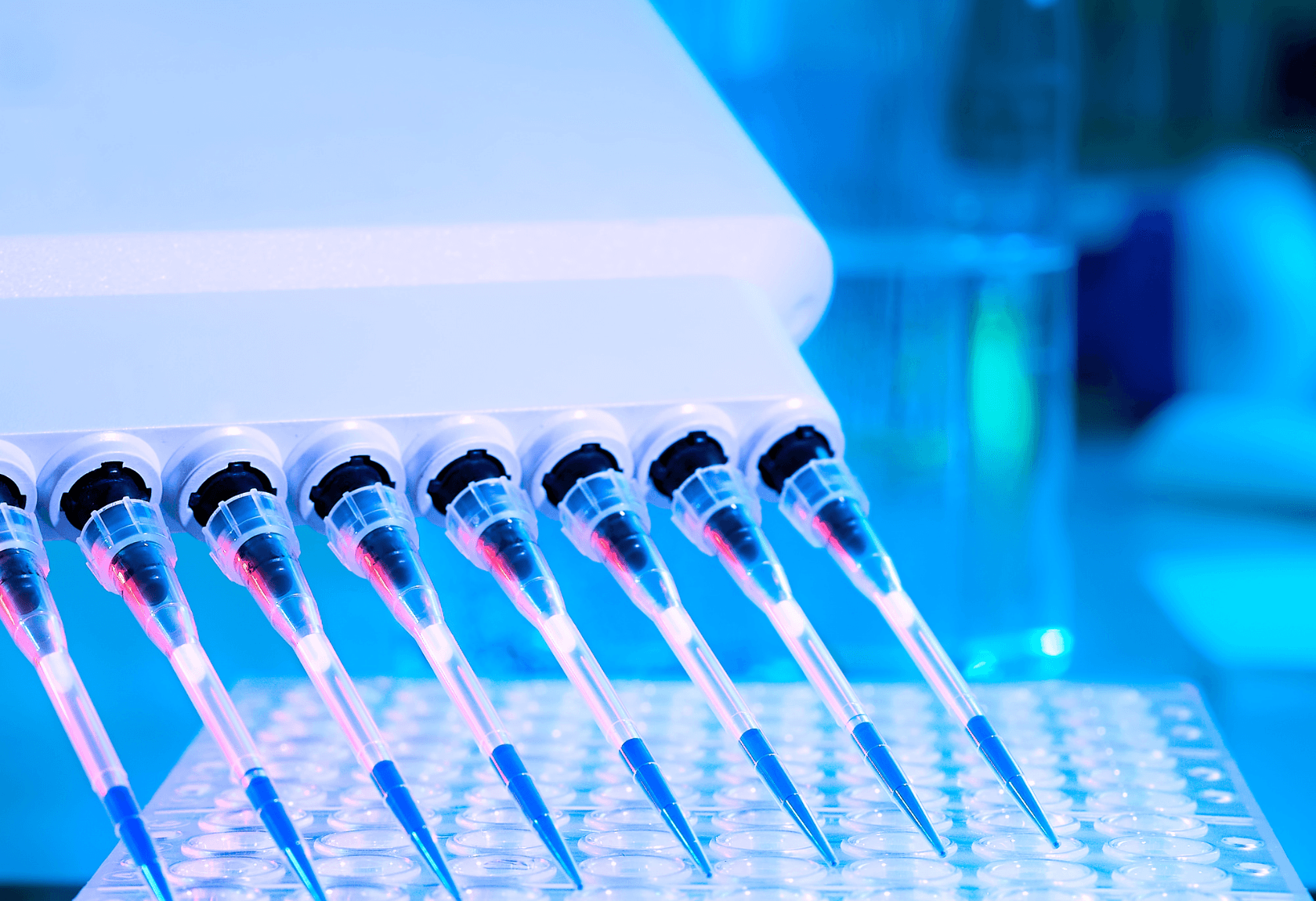

Reducing contamination

A slight contamination could lead to life-threatening conditions for patients. Pharma companies must adhere to stringent quality and safety measures during manufacturing. Traditional inspection methods are often riddled with errors and are time-consuming. The chances of contamination are very high in manual processes. That’s where computer vision helps. It meticulously scans empty bottles before adding medicine for foreign particles, cracks, and other anomalies. It ensures consistency in fill levels of vials and syringes and even checks for microbial contamination by analyzing images. This helps companies reduce contamination risks and improve the quality of their products.

Improving labeling accuracy

Mislabeling, smudges and printing errors, incomplete labeling, or inaccurate information are common labeling problems among pharma companies. To prevent counterfeit pills from entering the market and ensure patients have all the required information before consuming the drug, companies must improve labeling accuracy. Computer vision can scan the medicine labels for information like lot codes, expiry dates, and branding. This helps companies identify, seclude, and remove medicines that don’t match the labeling standards. It helps pharma companies maintain the sanctity of labeling. Companies can further improve the accuracy by training the machines to recognize different or distorted characters on the labels and separate them from the lot to enhance labeling accuracy and ensure patient safety.

Counting and packing pills accurately

Every pill counts for a patient, especially if they are consuming a life-saving drug. Thus, even one less pill in a bottle can put the patient’s life at risk. Counting and packing pills manually is cumbersome, particularly when workers do it manually. Fatigue sets in when workers have to see and count the pills continuously. That’s why it’s time for pharma companies to move away from using a counting tray and spatula to count the pills and replace them with AI-powered computer vision. Computer vision will use a camera to capture still images or video feeds of the pills, process the visual data using an AI algorithm, and give an accurate number of pills present in the image or the video feed. This will improve the accuracy of counting pills, save time, scale the business, and save people’s lives by packing the correct dosage.

Improve product sealing

Sometimes, pharma companies might inadvertently dispatch medicine bottles and strips that are not appropriately sealed, have cracks, misalignments, or poor closures. These lapses could contaminate the medicine, lead to medicine leakages, and affect the product’s integrity. Workers can prevent such lapses by using computer vision. They can place cameras along the packaging line to capture sealed container images in real-time, monitor them, and immediately identify sealing defects. This will help them check the seal alignments, ensure tamper-proof caps and closures of vials and bottles, and contain packages that are not sealed properly to avoid risking the patient’s health.

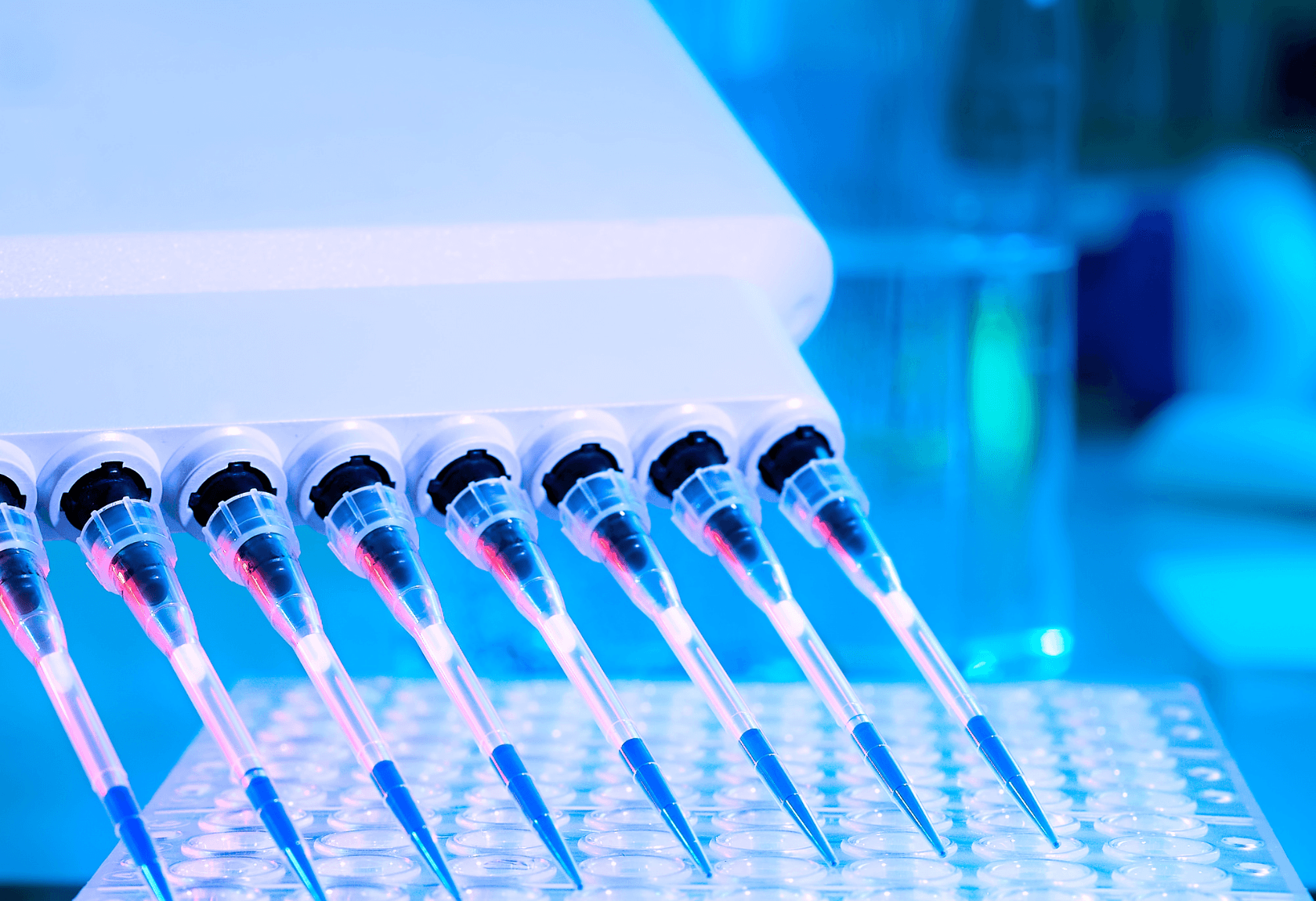

Don’t Undermine the Significance of Investing in AI-Powered Computer Vision

Manual inspections are complex, unreliable, and prone to errors if left unchecked. This can be dangerous, especially when companies manufacture at scale and involve patient safety. There’s no room for mistakes like dosage inaccuracy or something as serious as contamination.

Pharma companies can find it challenging to keep pace with the manufacturing scale and adhere to stringent compliance rules.

That’s why replacing manual inspections and automating inspection, labeling, and sealing is crucial to safeguard the pills from contamination and other risks.

InovarTech understands the complexity of quality inspection and has thus developed VisionGuard AI to simplify quality management, help companies conduct real-time inspections with precision, identify the most subtle defects, and improve compliance.

For more information on how VisionGuard AI can benefit your business, contact us.

Quality and product integrity are paramount in the pharmaceutical industry.

Even a minute lapse could lead to delays in product releases and drug shortages. If a lapse slips through the cracks and reaches patients, pharmaceutical companies will have to track and recall the drug, trace the errors, and do a root cause analysis to take immediate remedial action.

Besides being a long-drawn process, quality oversight could attract heavy fines for the company and damage its reputation.

The obvious solution is to improve the quality of products. However, it’s not simple.

While regulations like the Drugs Administration’s (FDA) Good Manufacturing Practices (GMP) and the World Health Organization’s (WHO) basic frameworks call for strict compliance, pharmaceutical companies are having trouble complying with them.

There could be various reasons for that:

Manufacturers have no control over raw materials or suppliers and no process for accepting or rejecting the materials

Human errors like skipping or repeating a step, lack of skills to perform tasks, non-adherence due to complex instructions, and more

Old or faulty equipment that could affect a drug’s quality

Other inconsistencies like discoloration of capsule surfaces and injection solution, cracks or splits in capsules, variations in the volume of pills and liquids in an injection vial, and sediments and particulate matter in injections, eyedrops, and syrups

Inaccurate pill counting due to incorrect scooping technique or human oversight, which could lead to less than prescribed medicines being packed in the bottle

Labeling issues such as smudges due to dirty printer rollers, printing and spelling errors, and incomplete or inaccurate information

The list is endless, and it’s clear that manual intervention is not enough for pharma companies to perform quality checks and ensure patient safety.

Automating quality control and using AI-powered computer vision is the only way to mitigate these issues.

How AI-Powered Computer Vision Can Help Pharma Companies Maintain Product Integrity and Patient Safety

In 2021, the European Journal of Pharmaceutical Sciences published a study on computer vision applications in pharmaceutical technology. The study’s objective was to understand how computer vision, digital cameras, and image analysis software could help pharmaceutical companies improve the efficiency and reliability of pharmaceutical manufacturing.

The study involved using digital cameras to capture images of pharmaceutical processes and materials, processing the images for analysis, segmenting them, and leveraging computer vision to monitor pharmaceutical processes like crystallization, granulation, and tablet coating.

The experiment demonstrated that computer vision can help pharma companies analyze the size, shape, color, and texture of different pharmaceutical materials and enhance the quality of medicines.

Let’s look at more use cases to understand how computer vision can play a role in product integrity and patient safety.

Reducing contamination

A slight contamination could lead to life-threatening conditions for patients. Pharma companies must adhere to stringent quality and safety measures during manufacturing. Traditional inspection methods are often riddled with errors and are time-consuming. The chances of contamination are very high in manual processes. That’s where computer vision helps. It meticulously scans empty bottles before adding medicine for foreign particles, cracks, and other anomalies. It ensures consistency in fill levels of vials and syringes and even checks for microbial contamination by analyzing images. This helps companies reduce contamination risks and improve the quality of their products.

Improving labeling accuracy

Mislabeling, smudges and printing errors, incomplete labeling, or inaccurate information are common labeling problems among pharma companies. To prevent counterfeit pills from entering the market and ensure patients have all the required information before consuming the drug, companies must improve labeling accuracy. Computer vision can scan the medicine labels for information like lot codes, expiry dates, and branding. This helps companies identify, seclude, and remove medicines that don’t match the labeling standards. It helps pharma companies maintain the sanctity of labeling. Companies can further improve the accuracy by training the machines to recognize different or distorted characters on the labels and separate them from the lot to enhance labeling accuracy and ensure patient safety.

Counting and packing pills accurately

Every pill counts for a patient, especially if they are consuming a life-saving drug. Thus, even one less pill in a bottle can put the patient’s life at risk. Counting and packing pills manually is cumbersome, particularly when workers do it manually. Fatigue sets in when workers have to see and count the pills continuously. That’s why it’s time for pharma companies to move away from using a counting tray and spatula to count the pills and replace them with AI-powered computer vision. Computer vision will use a camera to capture still images or video feeds of the pills, process the visual data using an AI algorithm, and give an accurate number of pills present in the image or the video feed. This will improve the accuracy of counting pills, save time, scale the business, and save people’s lives by packing the correct dosage.

Improve product sealing

Sometimes, pharma companies might inadvertently dispatch medicine bottles and strips that are not appropriately sealed, have cracks, misalignments, or poor closures. These lapses could contaminate the medicine, lead to medicine leakages, and affect the product’s integrity. Workers can prevent such lapses by using computer vision. They can place cameras along the packaging line to capture sealed container images in real-time, monitor them, and immediately identify sealing defects. This will help them check the seal alignments, ensure tamper-proof caps and closures of vials and bottles, and contain packages that are not sealed properly to avoid risking the patient’s health.

Don’t Undermine the Significance of Investing in AI-Powered Computer Vision

Manual inspections are complex, unreliable, and prone to errors if left unchecked. This can be dangerous, especially when companies manufacture at scale and involve patient safety. There’s no room for mistakes like dosage inaccuracy or something as serious as contamination.

Pharma companies can find it challenging to keep pace with the manufacturing scale and adhere to stringent compliance rules.

That’s why replacing manual inspections and automating inspection, labeling, and sealing is crucial to safeguard the pills from contamination and other risks.

InovarTech understands the complexity of quality inspection and has thus developed VisionGuard AI to simplify quality management, help companies conduct real-time inspections with precision, identify the most subtle defects, and improve compliance.

For more information on how VisionGuard AI can benefit your business, contact us.

Get in Touch

Get in Touch

Related Blogs

Related Blogs

Related Blogs

Related Blogs

Join our Newsletter 👇,

Join our Newsletter 👇,

Join our Newsletter 👇,

Join our Newsletter 👇,

Want the latest technology updates & business trends in your inbox? Subscribe to our newsletter and experience reading really interesting and informative.

Want the latest technology updates & business trends in your inbox? Subscribe to our newsletter and experience reading really interesting and informative.

Your email address

Sign me up

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

Explore more topics

Ready to brush up on something new? We've got more to read right this way.

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved

TECH

Inspire

Ideate

Inovate

Reach Out to Us :

Copyright © 2025 InovarTech. All rights reserved